Composiet fenders

RuplaTec heeft de meest voorkomende Composiet fenders op voorraad. Door onze uitgebreide productie faciliteiten is RuplaTec instaat om vrijwel alle mogelijke soorten Composiet fenders te produceren.

Collectie: Composiet fenders

-

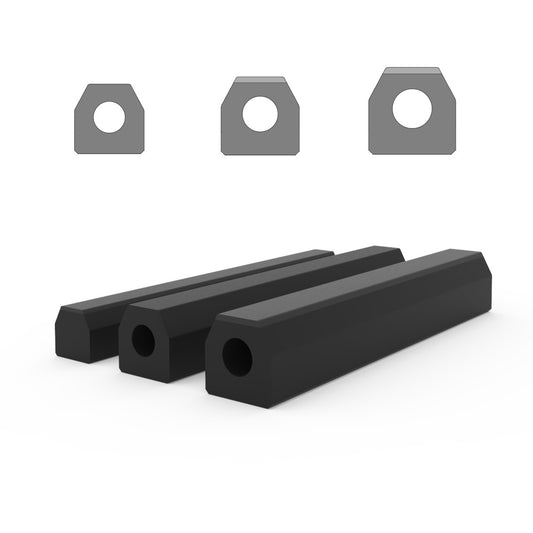

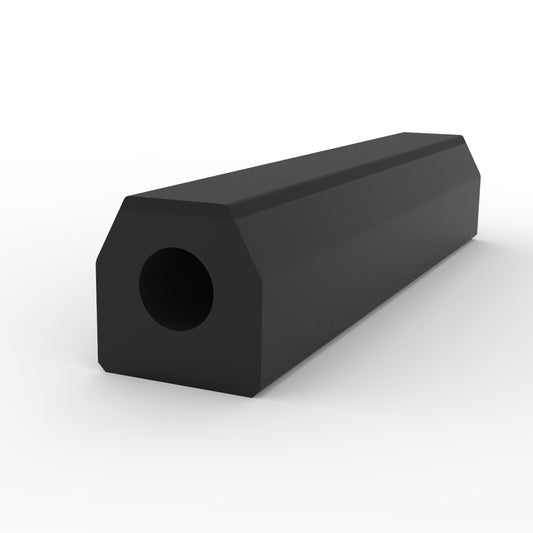

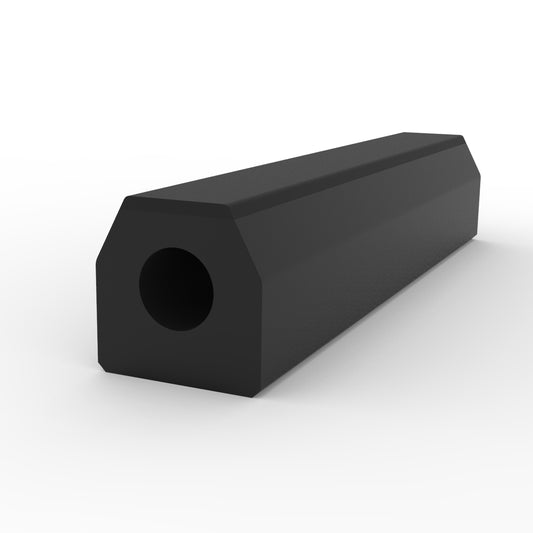

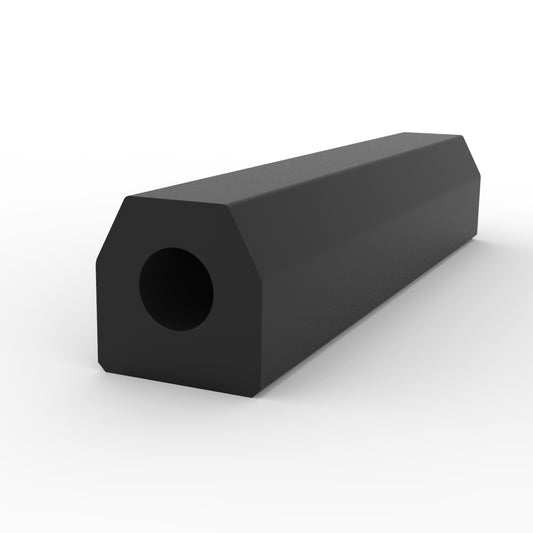

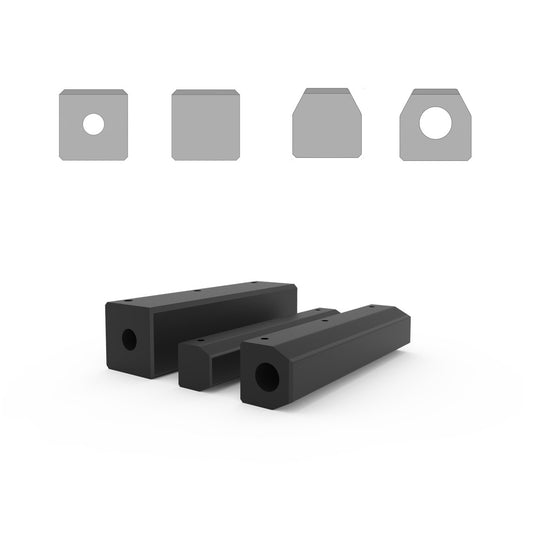

Trapeziumfenders

Normale prijs €0,01 EURNormale prijsEenheidsprijs / per -

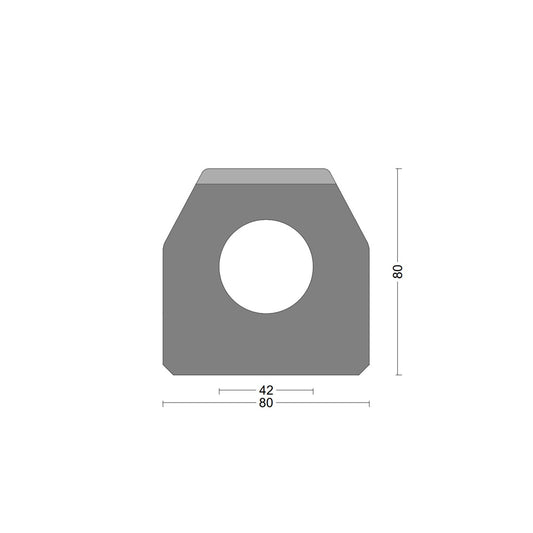

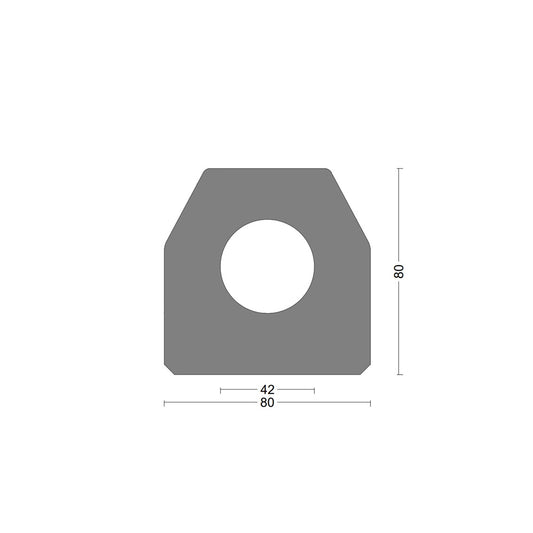

CF-C trap. Composite fender 80x80mm o-bore 42

Normale prijs €0,01 EURNormale prijsEenheidsprijs / per -

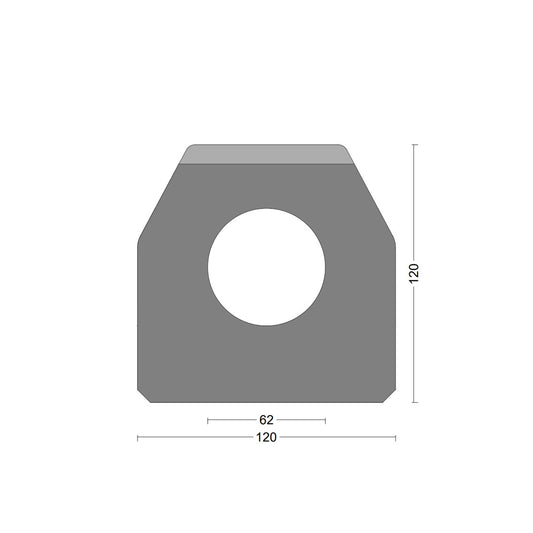

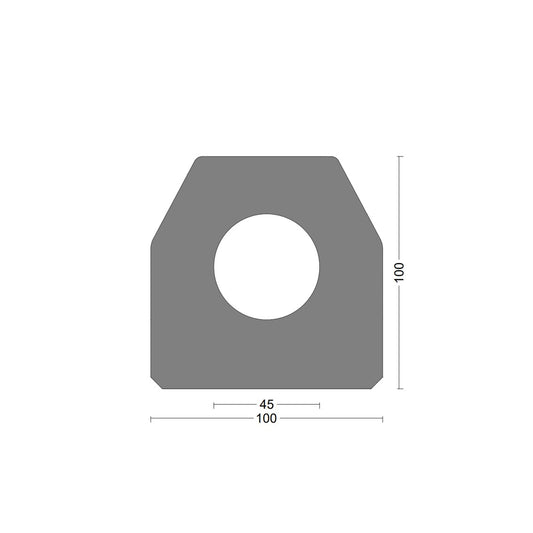

CF-C trap. Composite fender 120x120mm o-bore 62

Normale prijs €0,01 EURNormale prijsEenheidsprijs / per -

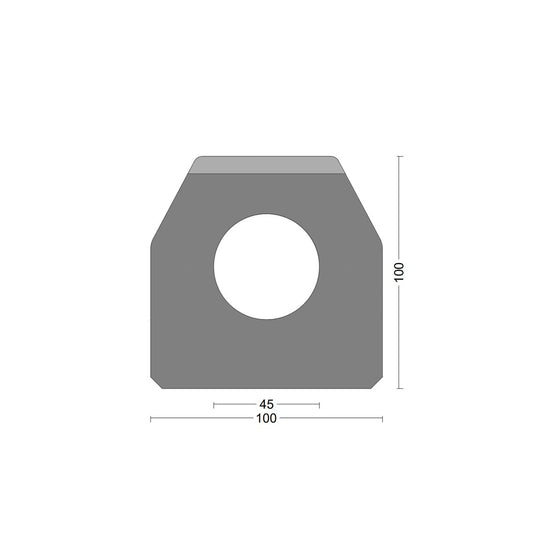

CF-C trap. Composite fender 100x100mm o-bore 45

Normale prijs €0,01 EURNormale prijsEenheidsprijs / per -

CF trap fender 80x80mm o-bore 42

Normale prijs €0,01 EURNormale prijsEenheidsprijs / per -

CF trap fender 100x100mm o-bore 45

Normale prijs €0,01 EURNormale prijsEenheidsprijs / per -

Composiet rubber- en UHMWPE-fenderblokken

Normale prijs €0,01 EURNormale prijsEenheidsprijs / per

Maatwerk oplossingen

Kunt u het door u gewenste product niet vinden? We gaan geen uitdaging uit de weg en maken Composiet fenders in eigen werkplaats met onze uitgebreide productiefaciliteiten.

-

Uitgebreide voorraad

RuplaTec beschikt over een ruime productie- en magazijnafdelingen. Ons brede assortiment van technische rubber en kunststof producten bevat meer dan 12.000 uit voorraad leverbare artikelen

-

Maatwerk oplossingen

We hechten veel belang aan een prettige klantervaring. Ons team biedt u graag branchegericht advies over maatwerkoplossingen en begeleidt u gedurende het gehele proces.

-

Korte levertijden

Onze strategische positie in de buurt van de haven van Rotterdam stelt ons in staat om snel te kunnen leveren binnen Nederland en Europa.

-

{"type":"root","children":[{"type":"text","value":"Competitieve prijzen","bold":true}]}

Met onze productie-expertise en geavanceerde faciliteiten leveren wij kwaliteitsproducten tegen scherpe prijzen. Vraag vandaag nog een gratis offerte aan.

-

+50 jaar industriële ervaring

Met meer dan 50 jaar ervaring in de productie en levering van alle vormen van Technisch rubber en Kunststoffen kunnen wij onze klanten vrijwel altijd de juiste oplossing bieden.

High Density Polyethylene (HDPE) specifiactions

HDPE (High-Density Polyethylene) is a strong and versatile plastic with excellent chemical resistance and very good mechanical properties. It is widely used in applications where durability, impact resistance and long-term reliability are required. HDPE performs well in chemically aggressive environments and retains its mechanical properties during use. However, it is not suitable for high-temperature applications.

Temperature range: −50 °C to +80 °C

At RuplaTec, HDPE is available as HDPE sheets and HDPE strips, supplied in standard sizes or fully custom-made.

Properties of High-Density Polyethylene (HDPE)

| Chemical resistance | Excellent |

| Impact strength | High |

| Durability | High, long service life |

| Weather resistance | Good |

| Ozone resistance | Good |

| Tensile strength | High |

| Abrasion & tear resistance | Good |

| Moisture absorption | Very low |

| Electrical insulation | Good |

| Mechanical stability | Retains properties during use |

| Maximum continuous temperature | 80 °C |

Applications of High-Density Polyethylene (HDPE)

- Pipes and fittings: Chemically resistant piping systems for industrial and residential use.

- Containers and tanks: Safe storage of chemicals, oils and liquids.

- Cutting boards: Food-safe, low moisture absorption and easy to clean.

- Geomembranes: Landfill liners, pond liners and environmental protection.

- Packaging: Blow-molded bottles and containers for chemicals and detergents.

- Wear strips and pads: Protection against abrasion and mechanical wear.

- Playground equipment: Durable and UV-resistant for outdoor use.

- Industrial components: Machine parts, tanks and storage bins.

- Marine applications: Docks, buoys and boat components due to water resistance.

Custom CNC machining

We can CNC-cut HDPE into virtually any shape, including strips, gaskets and rings. Contact our team to discuss your project or request a quotation.