Contact us

FAQ

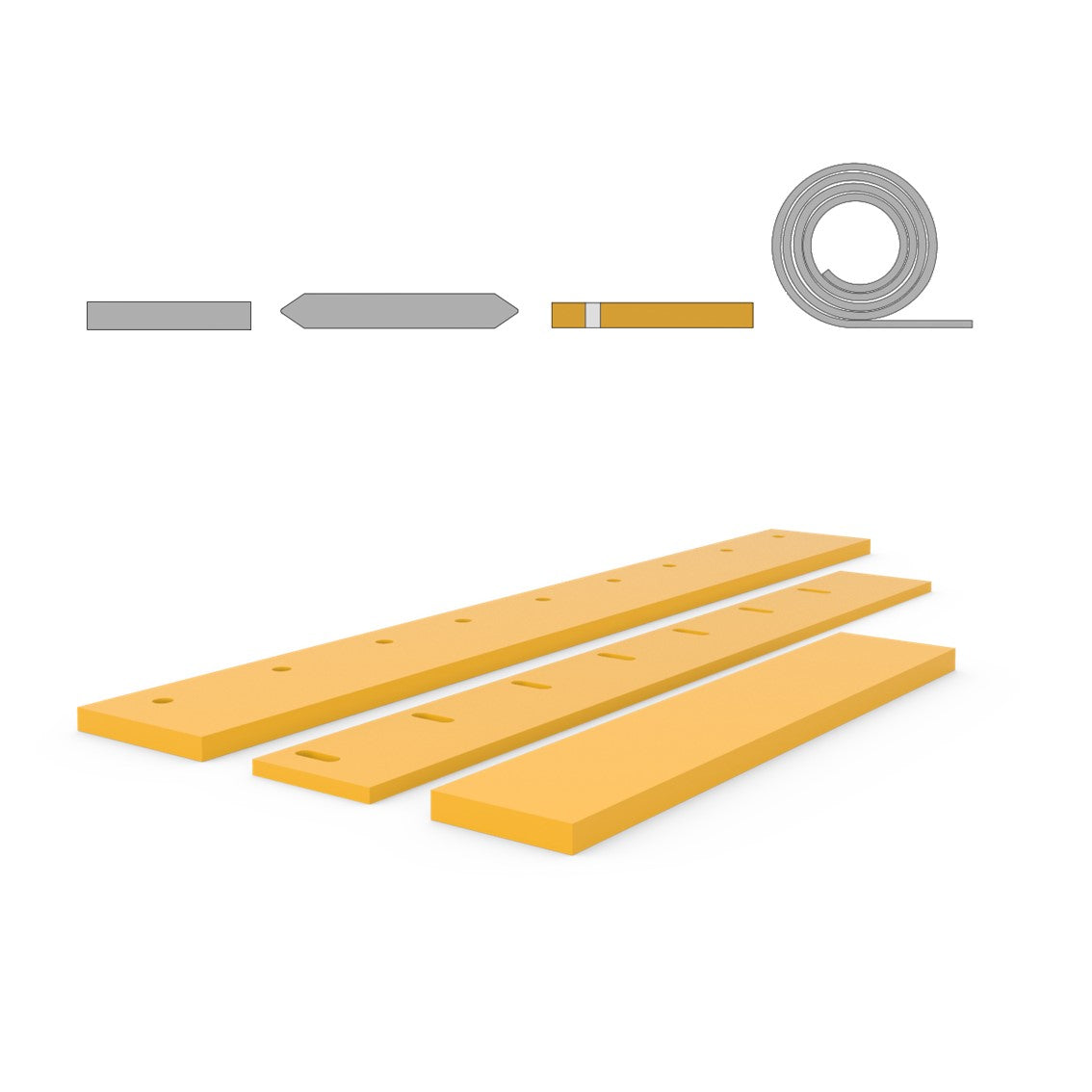

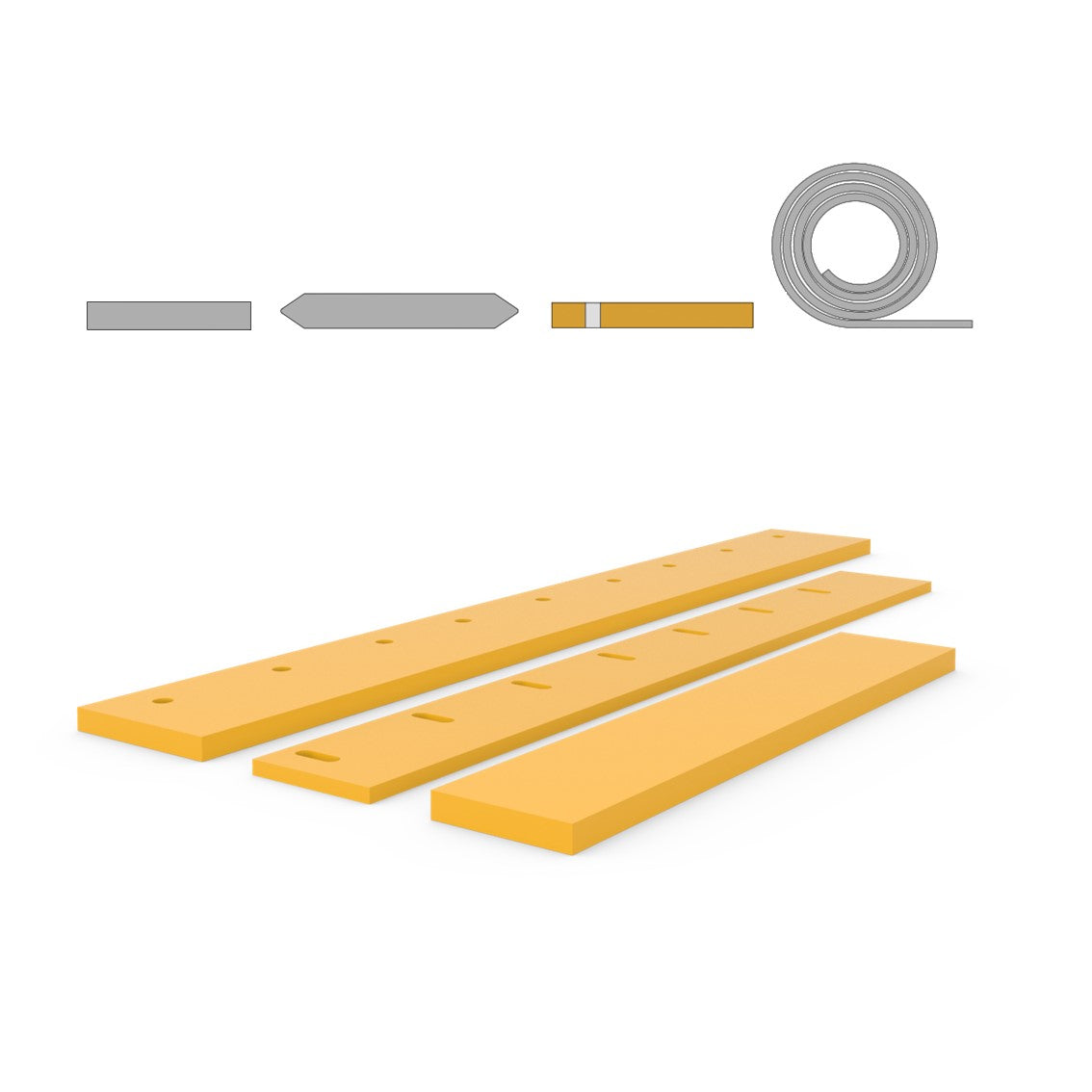

What are polyurethane yard scraper blades and what applications do they suit?

Polyurethane yard scraper blades are scraper edges fabricated from polyurethane elastomer intended for debris removal, surface cleaning, and material handling in yard and industrial settings. They are used where surface protection, reduced noise, and abrasion resistance are required, for example on loader buckets, sweepers, and yard scrapers. The term polyurethaan is an alternative spelling used in some markets. Selection depends on operational conditions such as substrate type, abrasive load and exposure to chemicals.

How do polyurethane yard scraper blades compare with traditional metal blades?

Compared with metal blades, polyurethane yard scraper blades typically offer increased impact absorption, reduced noise and improved protection of contact surfaces. They provide good abrasion resistance while remaining more flexible than steel. Limitations can include differing performance at extreme temperatures and potential chemical incompatibilities with certain solvents. Trade-offs between wear characteristics and surface preservation should be evaluated when choosing between polyurethane and metal blades for yard scraper applications.

How do I determine compatibility and select the correct type of yard scraper blade?

Selecting a compatible polyurethane yard scraper blade requires matching the blade profile, mounting method and material properties to the existing equipment and application. Review the scraper’s edge design, attachment points and operational stresses, and confirm hardness and compound suitability for the intended abrasives and environmental conditions. Consult equipment manufacturer guidelines or technical datasheets to verify fit and performance requirements. For markets using Dutch terminology, search for polyurethaan yard scraper blades with equivalent specifications.

What maintenance, inspection and storage practices are recommended for polyurethane blades?

Routine visual inspection for wear, cuts, delamination or mounting damage is recommended to ensure safe operation of polyurethane yard scraper blades. Clean blades of adherent debris and avoid prolonged exposure to incompatible chemicals that can degrade polyurethane. Store blades flat or supported to prevent deformation and keep them out of direct sunlight and extreme heat. Replacement should be based on observed wear that affects performance or secure mounting rather than a fixed interval, and any corrective action should follow equipment manufacturer procedures.