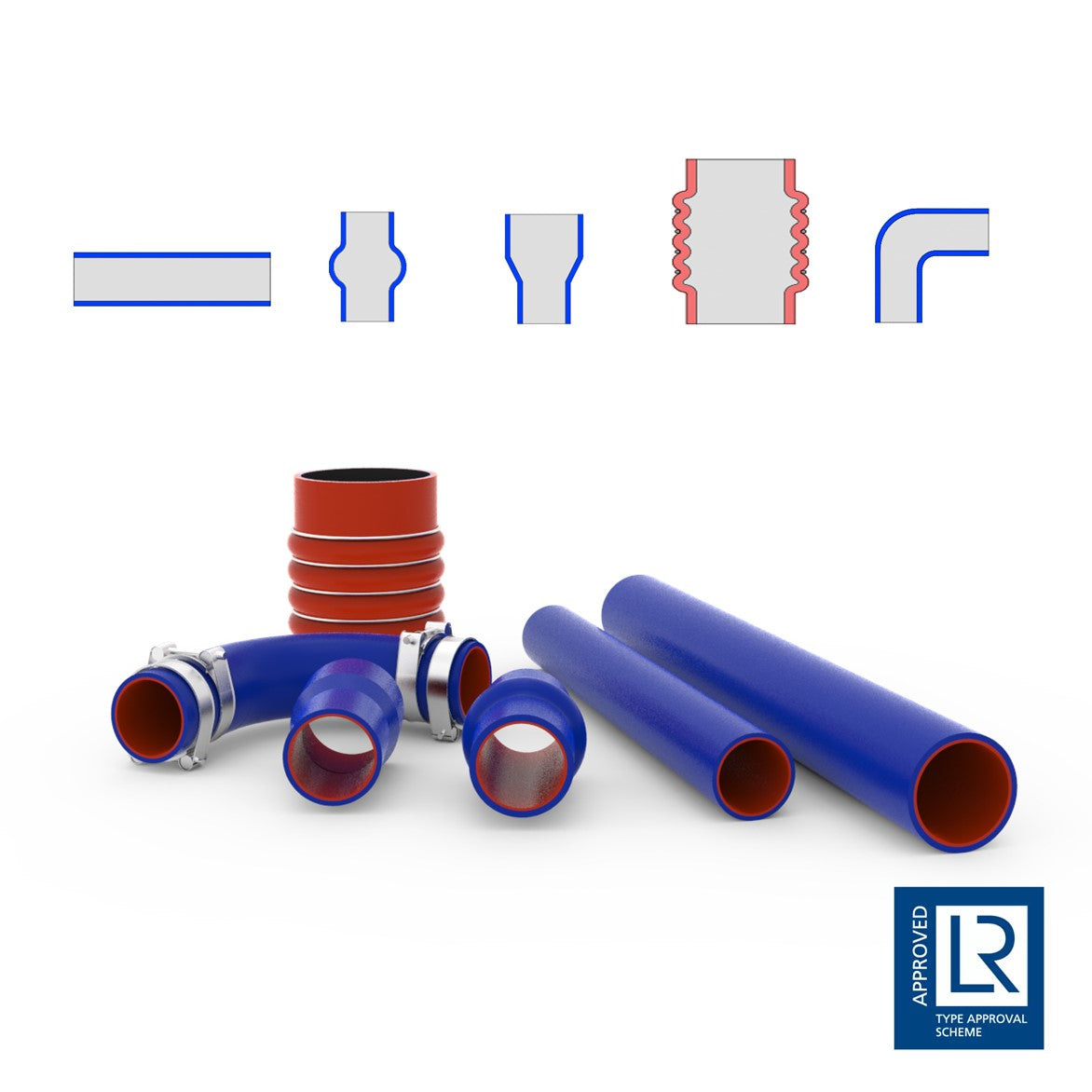

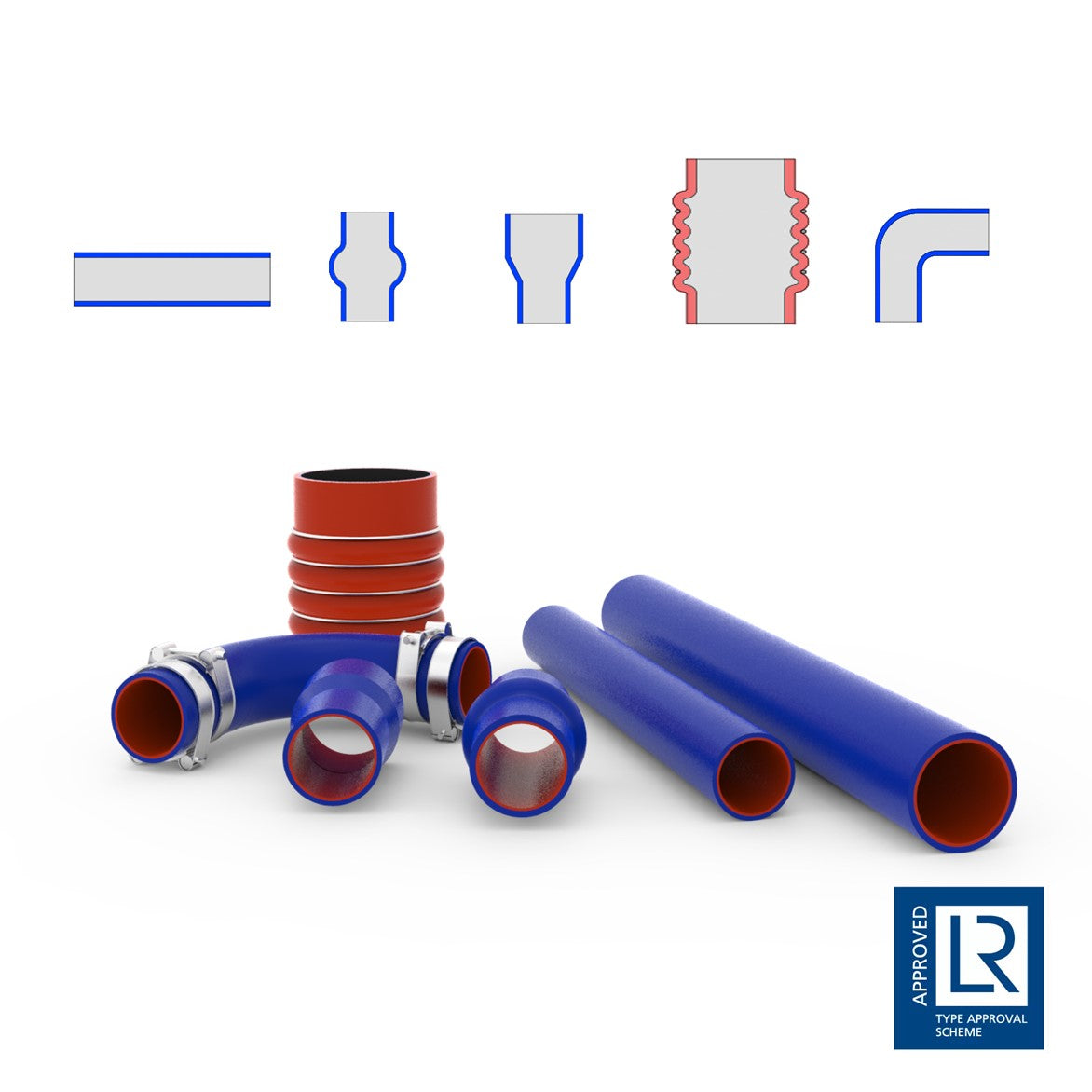

Silicone hoses: types, sizes and maritime variants

Silicone hoses and bellows are used across marine and industrial systems for flexible connections, vibration isolation and thermal resilience. RuplaTec supplies silicone hoses and bellows in a wide range of diameters and configurations to suit different routing and connection requirements. Variants include convoluted bellows, straight and reinforced hoses, and designs intended for use with clamp, flange or bespoke end fittings. Lloyd's Register-certified variants are available for customers who specify maritime certification.

Technical considerations and procurement support for silicone hoses

When selecting silicone hoses, consider operating temperature ranges, pressure and vacuum requirements, chemical compatibility with conveyed media, reinforcement type and flex life under cyclic movements. Attention to end-fitting compatibility, hose curvature and support arrangements helps avoid premature wear. Material certificates, test reports and certification information can be provided on request to support procurement and compliance reviews. For a broader view of available formats and sizes, see the silicone hoses collection: Silicone hoses collection. Contact our technical team for application advice, specification reviews or to discuss customised options relevant to your installation.