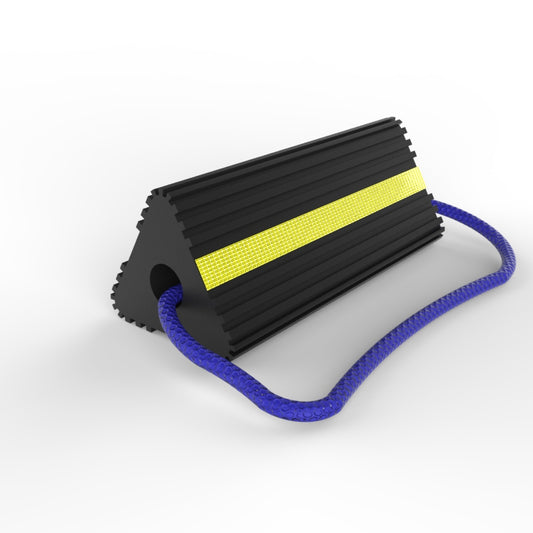

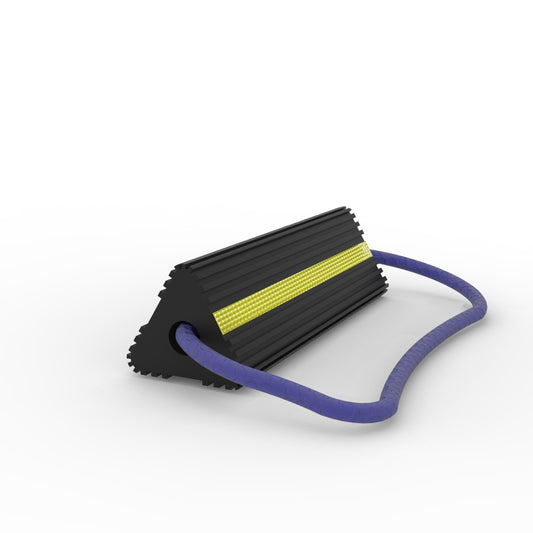

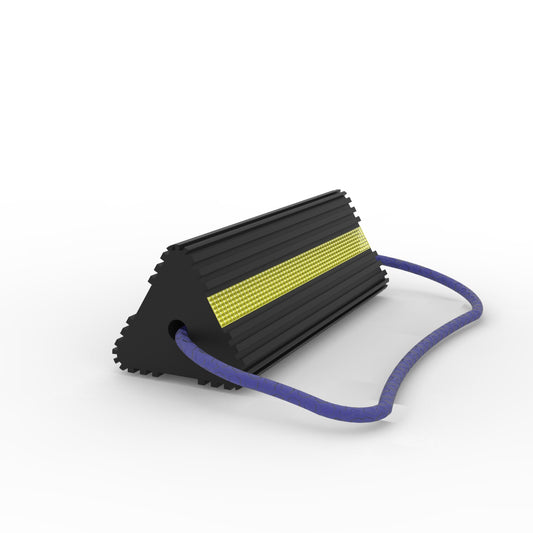

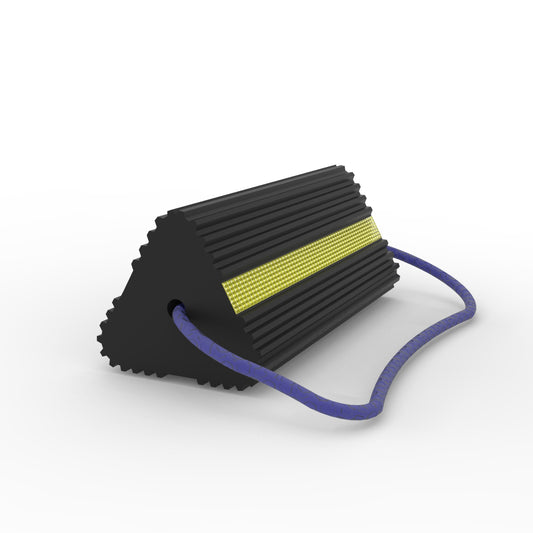

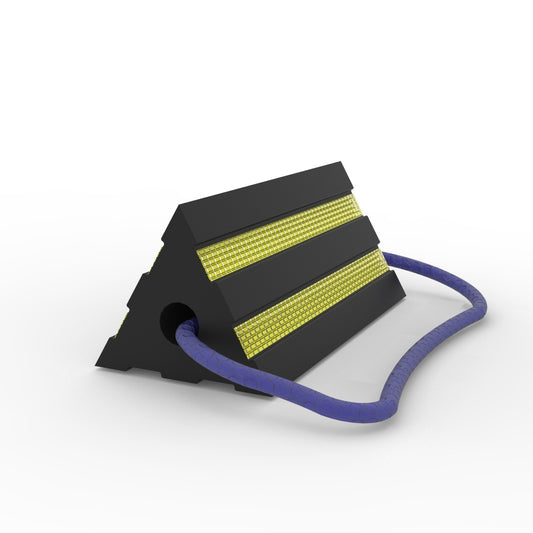

Fast Delivery of Aircraft Wheel Chocks in Europe

We deliver aircraft wheel chocks across Europe at speed from our EU warehouse, so your ground operations never have to wait.

Lead times & processing

- Orders processed within 24 hours.

- Typical delivery window: 1–5 business days (location dependent).

- Express options available on request.

Shipping coverage

EU & EFTA

Fast lanes to the EU single market and EFTA countries with predictable transit times and paperless workflows.

Non-EU Europe

Optimized routes for UK, Balkans and other non-EU destinations with clear customs handling.

Why choose RuplaTec

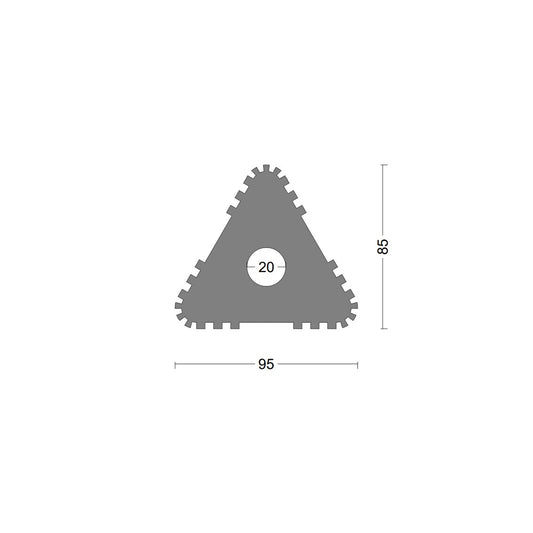

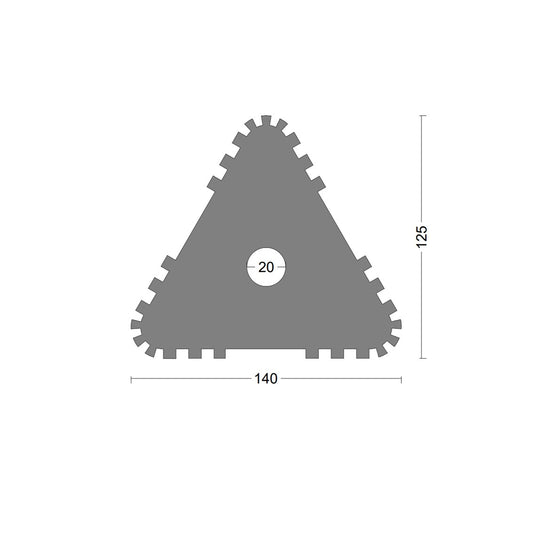

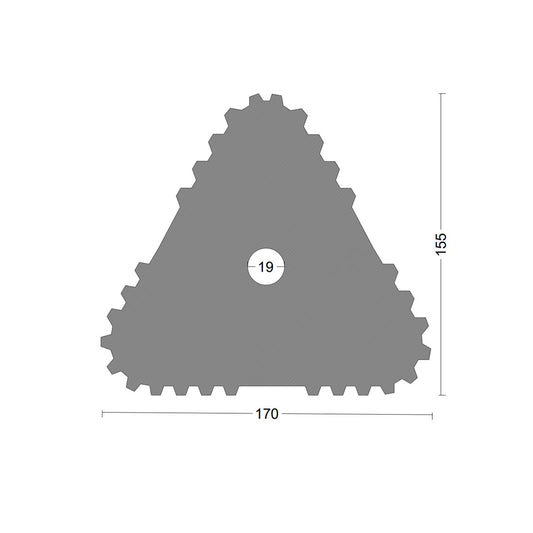

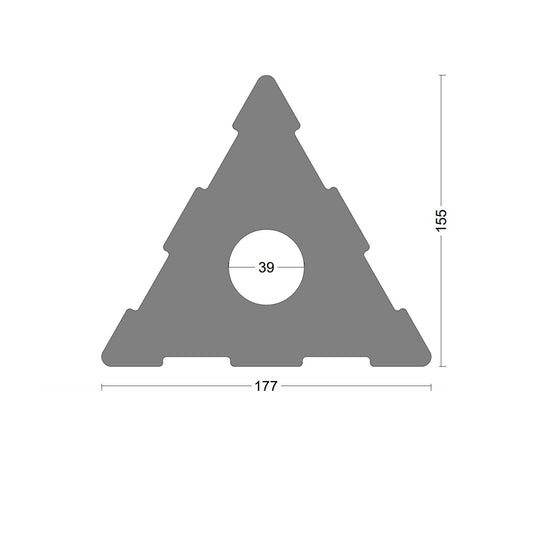

- Durable rubber/polyurethane chocks built for daily use.

- Stock on hand for fast turnaround.

- Reliable logistics partners across Europe.

Contact & ordering

Need an urgent shipment? Contact our team for the fastest route and a precise ETA.