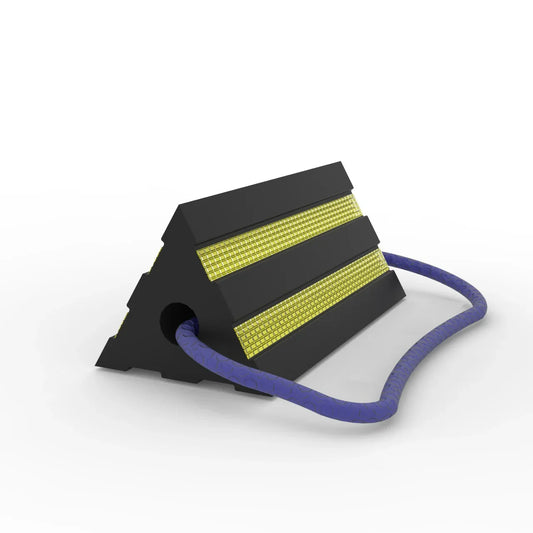

Aircraft wheel chocks

We stock a wide range of commonly used aircraft wheel chocks and can also manufacturecustom aircraft wheel chocks based on your specific design and operational requirements. Feel free to contact us to discuss your application or any bespoke project.

Collection: Aircraft wheel chocks

-

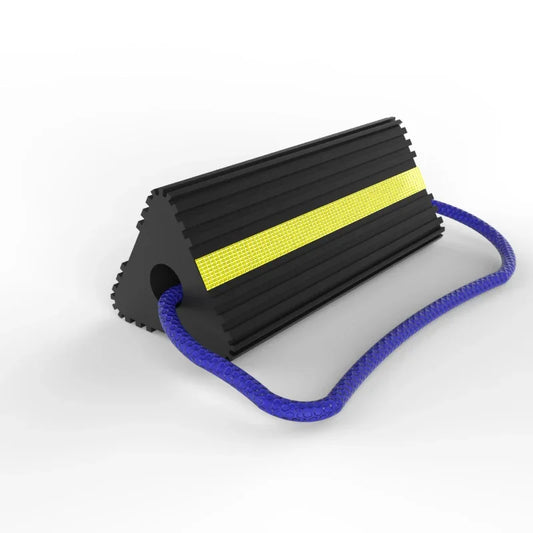

Aircraft wheel chocks

Regular price €0,01 EURRegular priceUnit price / per -

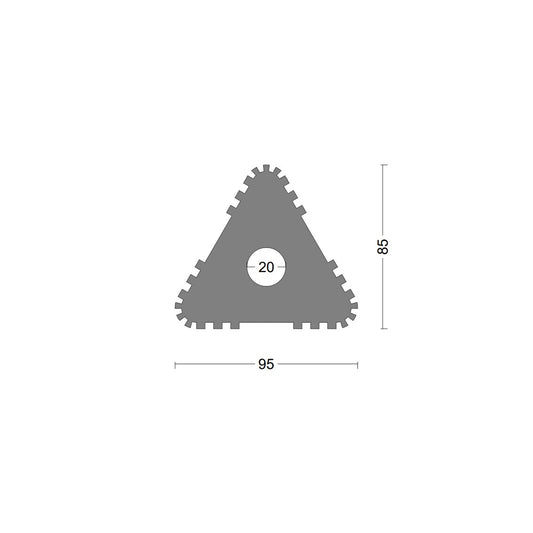

Aircraft Wheel chock 95x85mm

Regular price €0,01 EURRegular priceUnit price / per -

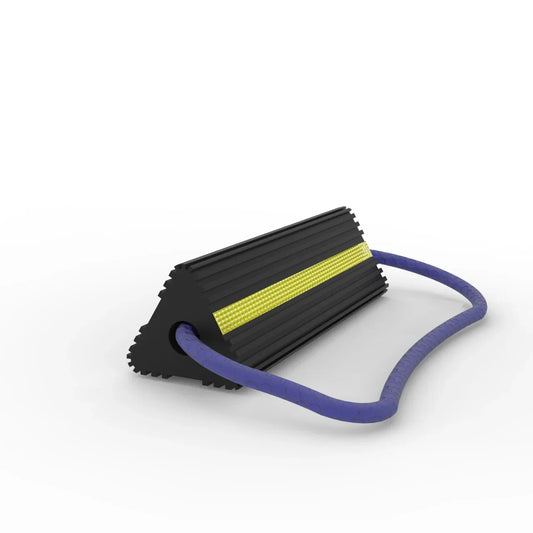

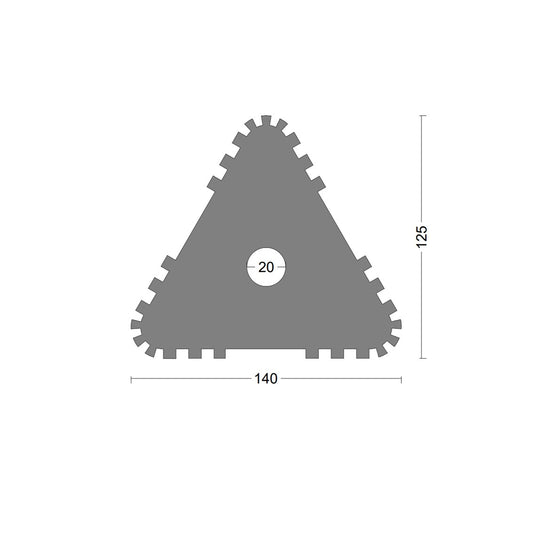

Aircraft wheel chocks rubber 140x125mm

Regular price €0,01 EURRegular priceUnit price / per -

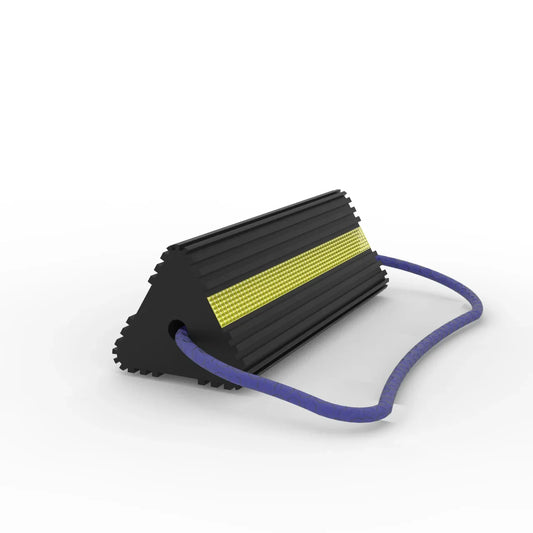

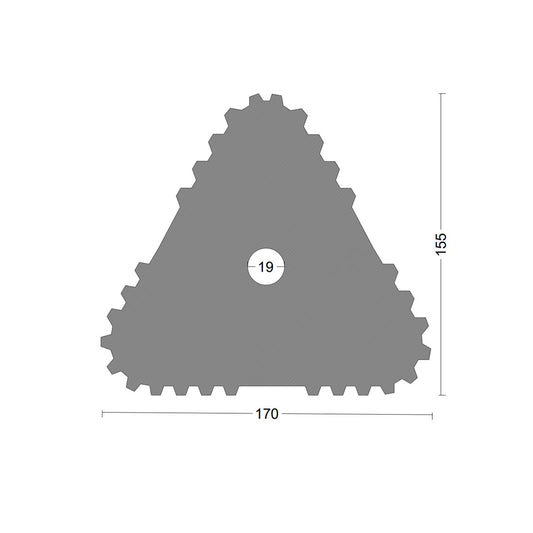

Aircraft Wheel chock rubber 170x155mm

Regular price €0,01 EURRegular priceUnit price / per -

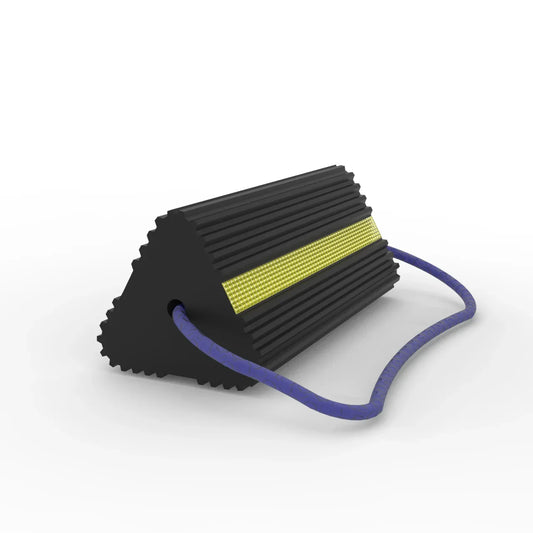

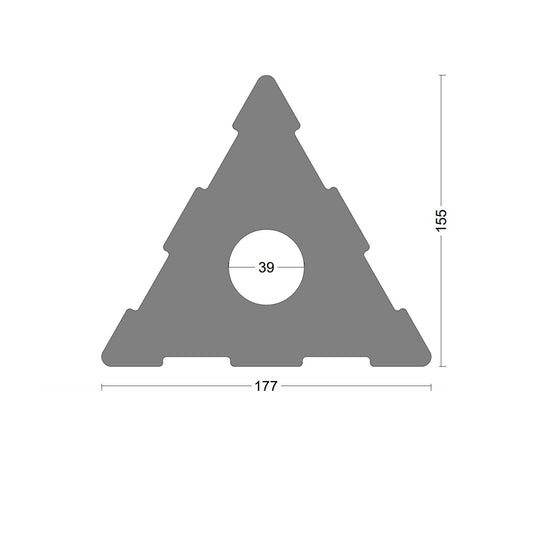

Aircraft Wheel chock 177x155mm

Regular price €0,01 EURRegular priceUnit price / per

AIRCRAFT WHEEL CHOCK BROCHURE

For detailed information and specifications of our aircraft wheel chocks, please refer to our brochure. Our team is available to assist you with any questions or technical guidance.

Custom aircraft wheelchocks

If you can't find what you're looking for, don't worry! We have the capability to manufacture Aircraft wheel chocks in practically any design you require.

What are aircraft wheel chocks?

Aircraft wheel chocks are used to secure parked aircraft during ground operations. They are positioned against the aircraft wheels to help prevent unintended movement and to support safe handling in aviation environments.

Applications of aircraft chocks

Aircraft chocks are used across aviation ground operations, including commercial aviation, general aviation and routine ground handling. Reliable grip and predictable performance are essential to help keep aircraft securely parked on common apron and hangar surfaces.

Aircraft wheel chocks are developed for the specific load conditions and tyre dimensions of aircraft. They typically provide a larger contact area and increased friction to ensure stability on tarmac and apron surfaces. In comparison, wheel chocks for general vehicles such as cars, trailers or campers are designed for lighter loads and different operating environments. For non-aviation applications, please see our wheel chocks collection.

Airplane wheel chocks

Aircraft wheel chocks are also commonly referred to as airplane chocks or plane wheel chocks. These terms describe the same type of wheel securing chock used for parked aircraft, with the correct choice depending on the operating environment and the chock design.

Rubber aircraft wheel chocks

This collection includes rubber aircraft wheel chocks designed to provide high friction and durability. Rubber chocks maintain stable contact with both the aircraft tire and the ground surface, reducing the risk of slipping during use.

-

Extensive inventory

Explore our extensive range of Aircraft wheel chocks, readily available for fast delivery, thanks to our well-maintained stock, ensuring fast fulfillment of your orders.

-

Bespoke custom types

We have the capacity to manufacture Aircraft wheel chocks according to client drawings or specifications, utilizing a wide range of materials to meet your needs.

-

Fast delivery in the EU & UK

Our strategic location close to the Port of Rotterdam, enables us to provide rapid and efficient deliveries to customers across Europe.

-

Competitively priced products

With our manufacturing expertise and advanced facilities, we provide quality products at competitive prices. Request a free quote today.

-

+ 50 years of industry experience

With over 50 years of industry experience, our experienced team is ready to assist you. Feel free to contact us with any questions about our products or services.