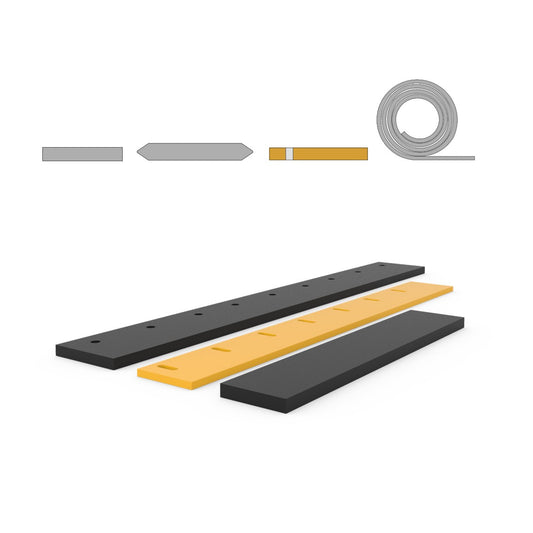

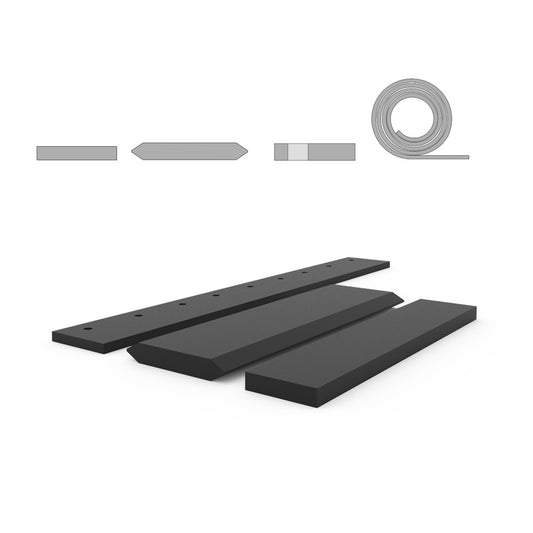

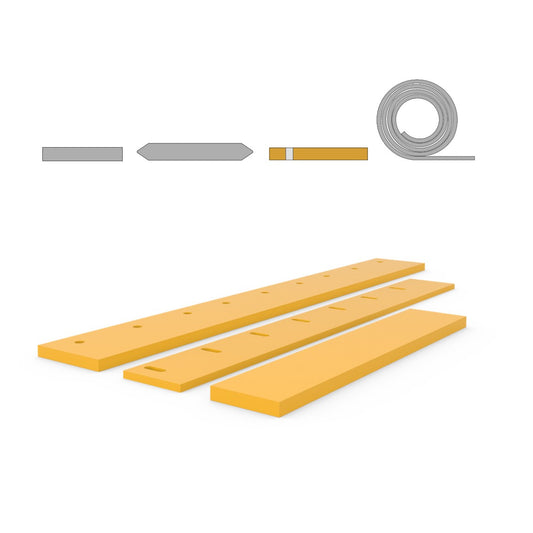

Collection: Scraper blades

-

Plastic scraper blades

Regular price €0,01 EURRegular priceUnit price / per -

Rubber snow plough blades

Regular price €0,01 EURRegular priceUnit price / per -

Polyurethane snowplough blades

Regular price €0,01 EURRegular priceUnit price / per -

Rubber yard scrapers

Regular price €0,01 EURRegular priceUnit price / per -

Polyurethane yard scraper blades

Regular price €0,01 EURRegular priceUnit price / per

What are scraper blades?

Scraper blades are wear components mounted to scraping equipment used for removing material from hard surfaces. They are designed to scrape, clean or level surfaces by maintaining controlled contact with the underlying substrate during operation.

Scraper blades are used in a wide range of applications where durability, consistent contact and predictable wear behaviour are required.

Scraper blades for different applications

Scraper blades are applied across multiple industries and operating environments. Typical uses include agricultural yards, industrial sites, logistics areas, infrastructure maintenance and surface cleaning operations.

Depending on the application, scraper blades may be used to remove dirt, residue, slurry, loose material or buildup from concrete, asphalt or other paved surfaces.

Replacement scraper blades

As scraper blades are subject to continuous friction and mechanical load, they are considered wear parts that require periodic replacement. Timely replacement helps maintain scraping efficiency and prevents unnecessary stress on the scraper frame or mounting system.

Replacement scraper blades are commonly installed as part of routine maintenance programs or during refurbishment of existing scraping equipment.

Materials, sizes and configurations of scraper blades

Scraper blades are available in different materials, selected according to flexibility, wear resistance and operating conditions. Material choice influences scraping performance, service life and surface protection.

Blades can be supplied in various lengths, thicknesses and mounting configurations to suit different scraper designs. Correct sizing and configuration are essential for proper fitment and reliable operation.

Related product groups

-

Polyurethane

What is polyurethane Polyurethane is a versatile synthetic polymer that can be...

-

Rubber sheets

What are rubber sheets? Rubber sheets are flat rubber materials used in...

-

Plastic Sheets

What are plastic sheets? Plastic sheets are flat plastic panels used in...