Contact us

FAQ

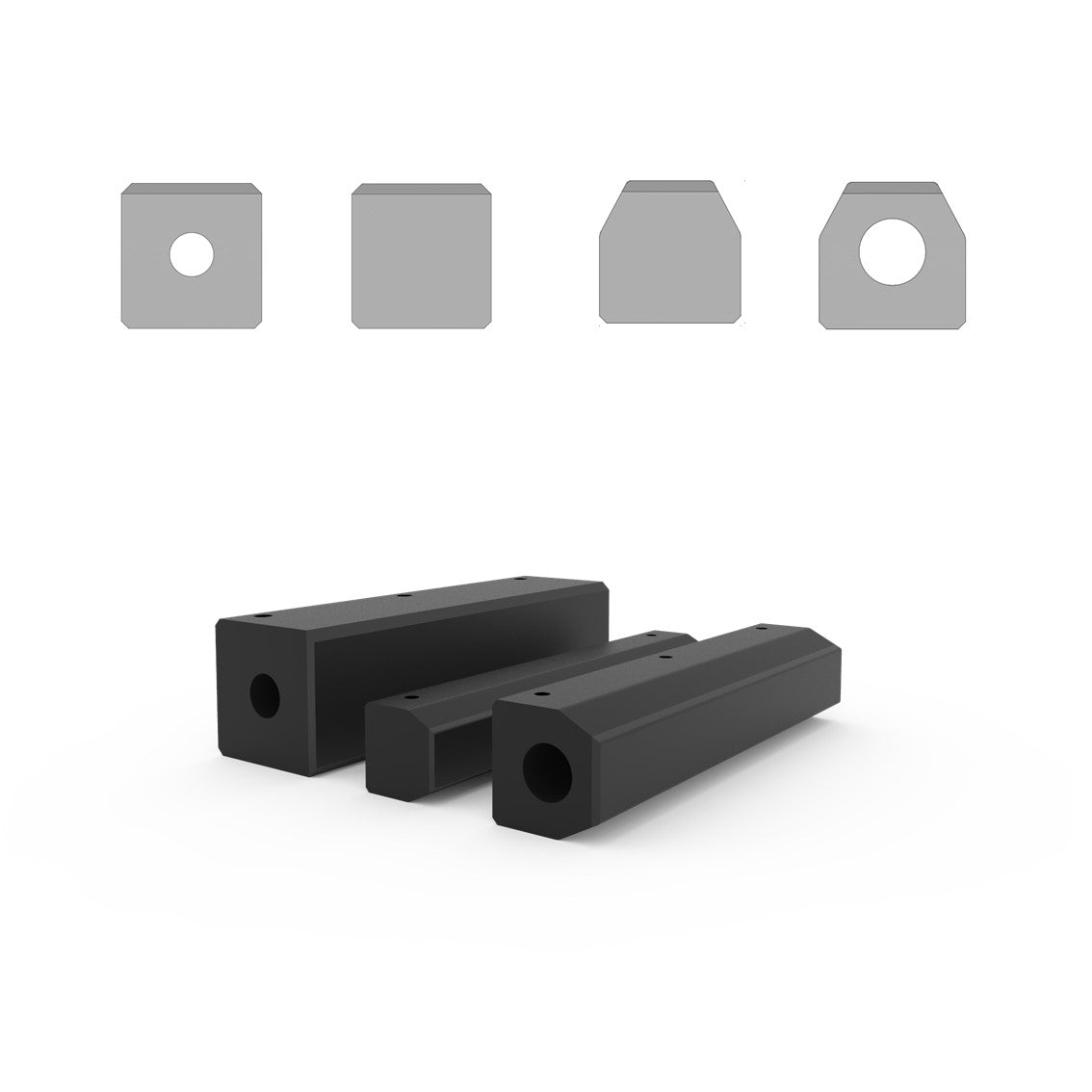

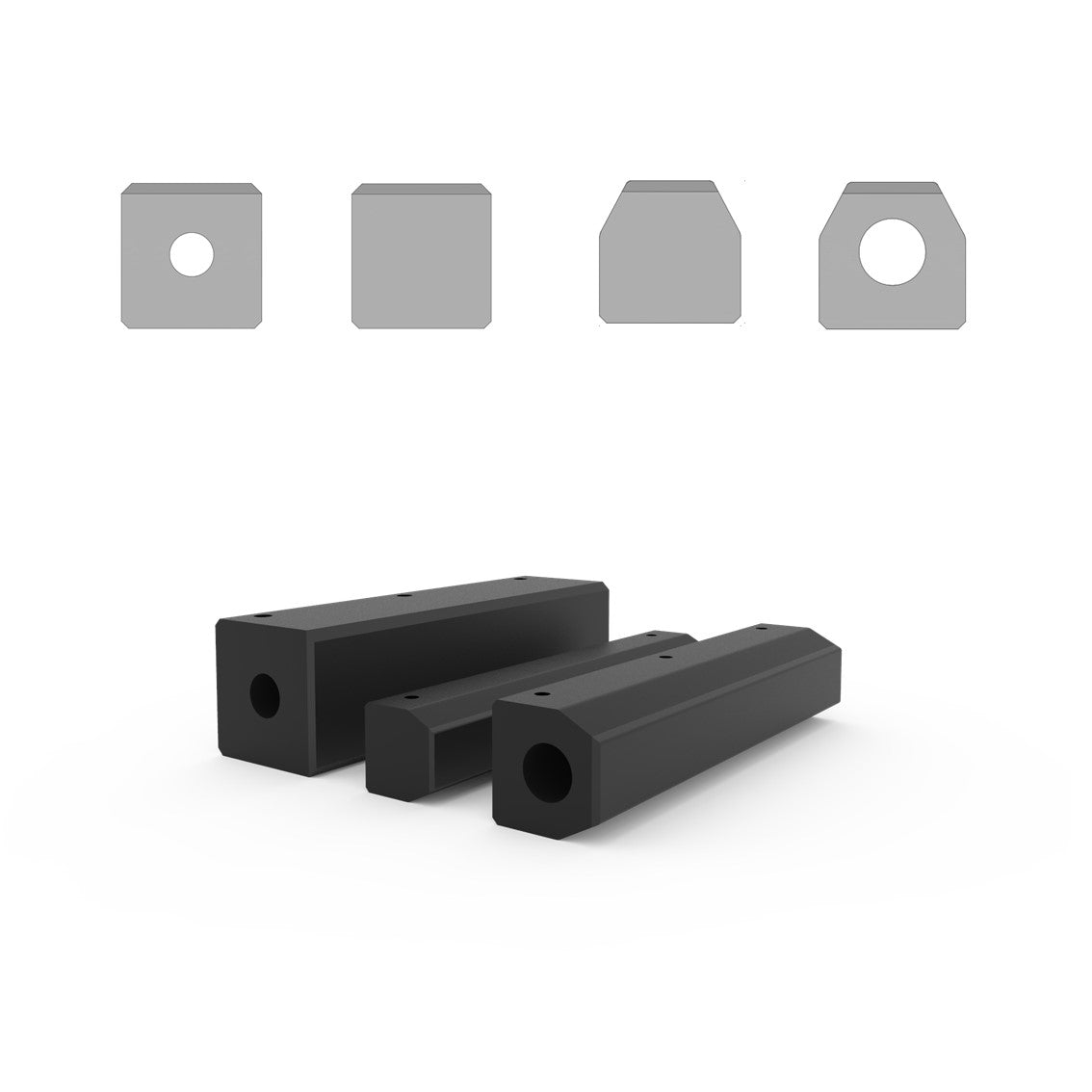

What are composite rubber & UHMWPE fender blocks?

Composite rubber & UHMWPE fender blocks are marine fender elements combining an elastomeric rubber profile with a wear-resistant UHMW-PE (ultra-high-molecular-weight polyethylene) coating. The UHMW-PE layer provides a low coefficient of friction at the contact surface while the rubber profile supplies a resilient backing. The two materials are bonded or mechanically connected to form a single block designed for repeated contact in berthing and mooring environments where reduced sliding friction and surface wear are required.

In which applications are composite fender blocks typically used?

Composite rubber & UHMWPE fender blocks are used in maritime berthing and mooring installations where surfaces are subject to sliding contact and abrasion. Common applications include quay walls, piers, pontoons, and vessel-side protection where controlled friction and surface wear resistance are priorities. Selection of a composite fender block should be matched to the specific operational environment, contact conditions, and installation method to ensure compatibility with the intended berthing or mooring arrangement.

What performance characteristics do these UHMW-PE coated fender blocks provide?

The primary performance characteristics of UHMW-PE coated composite fender blocks are surface wear resistance and a low coefficient of friction at the contact interface. The UHMW-PE coating reduces abrasion and sliding resistance, while the rubber profile provides a resilient backing to accommodate contact loads. Together, these properties address sliding and abrasive contact scenarios by limiting surface wear and lowering frictional forces at berthing interfaces.

What are the recommended maintenance and installation considerations?

Installation and maintenance depend on block type, mounting arrangement, and site conditions. Follow supplier installation instructions for fastenings, alignments, and anchorage. Routine maintenance typically includes periodic inspection of the UHMW-PE coating and rubber interface for excessive wear, verification of attachment integrity, and removal of accumulated debris or abrasive particles. Replace blocks when wear or damage compromises their functional surface or attachment. Consult product documentation for specific service and replacement criteria.