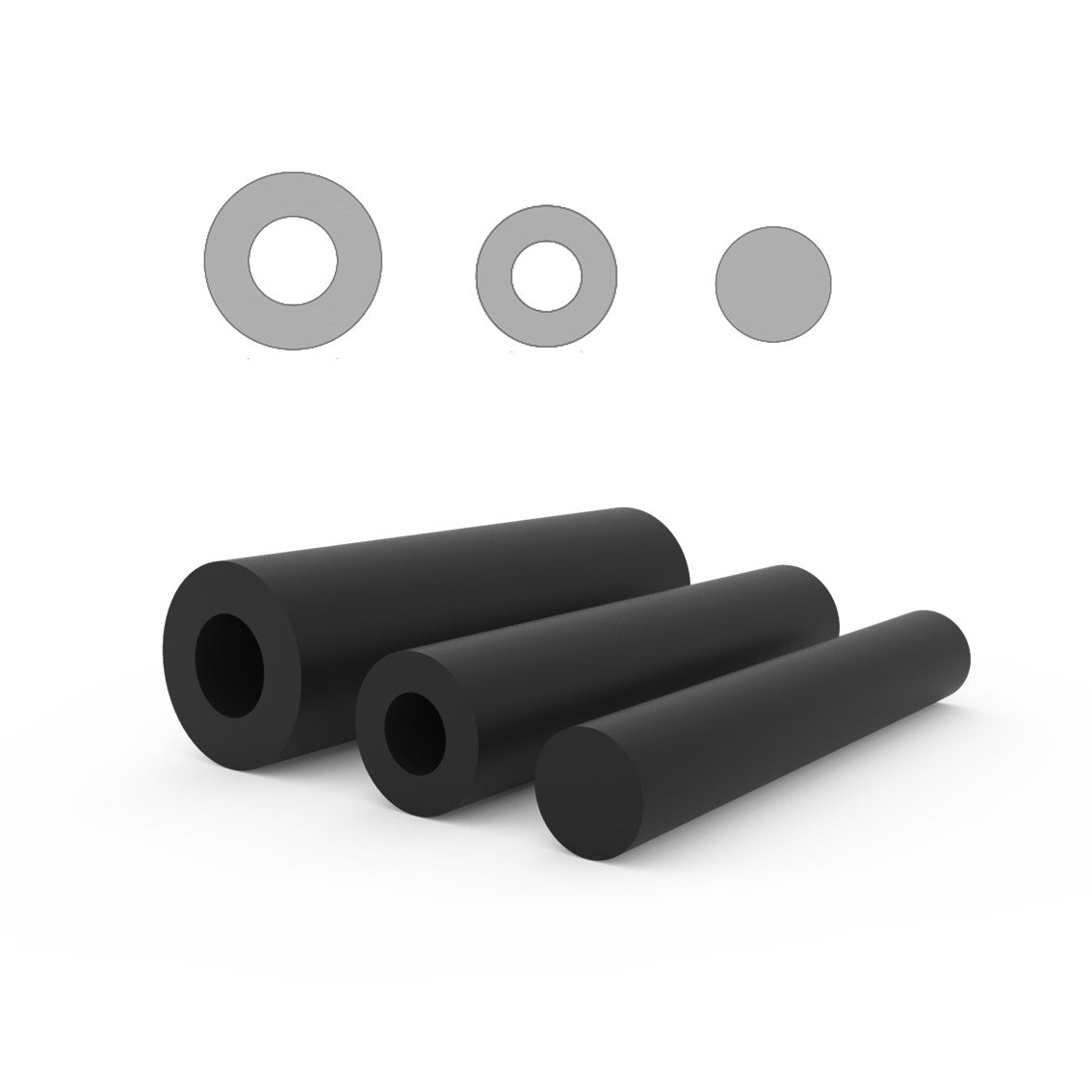

Cylindrical fenders: product overview

Cylindrical fenders are a common choice for soft, forgiving contact between vessels and fixed structures. They are available in a range of diameters, lengths and materials to suit different hull types and mooring arrangements. RuplaTec supplies a selection of cylindrical fenders and related accessories; details on available types and sizes can be found in the cylindrical fenders collection. The stocked range covers small craft through to larger recreational and workboats, with items suitable for vessels from around 4 metres to over 12 metres in length.

Applications and sizing for cylindrical quay fenders

Cylindrical quay fenders are used in berthing, berth protection and alongside-fendering applications where a linear contact profile is required. Selection typically considers vessel length, displacement, berthing speed and required energy absorption. Installation context—such as deck, quay or pontoon mounting—and attachment method influence the appropriate diameter, length and hardness. For procurement and specification, confirm the intended operating conditions so that size and material choices align with the expected loads and mounting arrangement.

Technical information and procurement guidance

Technical data, material options and installation accessories may be available on request to support specification and tender documentation. Consider maintenance access, inspection intervals and repairability when comparing alternatives. If assistance is needed in assessing suitability or specifying fender dimensions and mounting details, contact our team for advice and to request technical information relevant to your project.