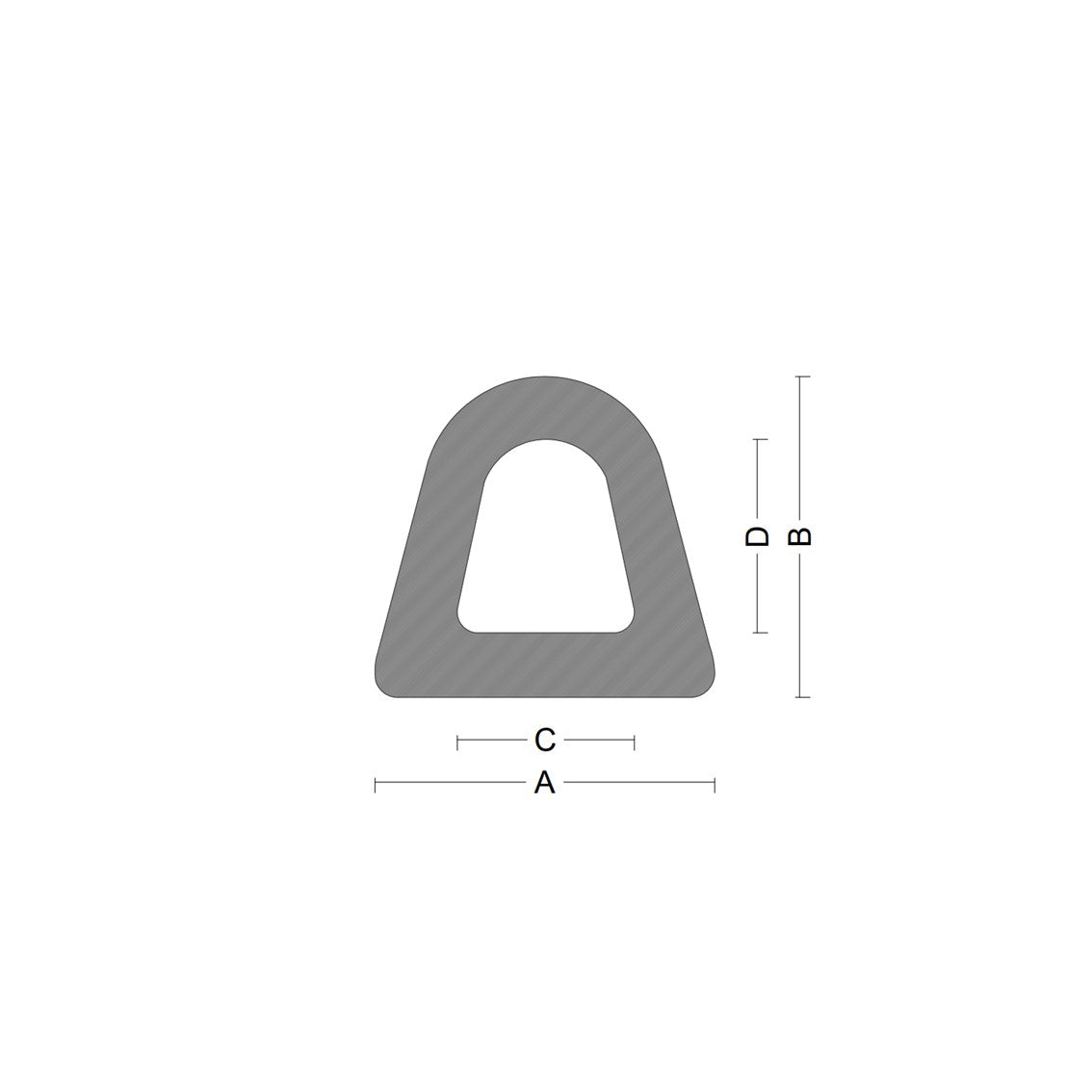

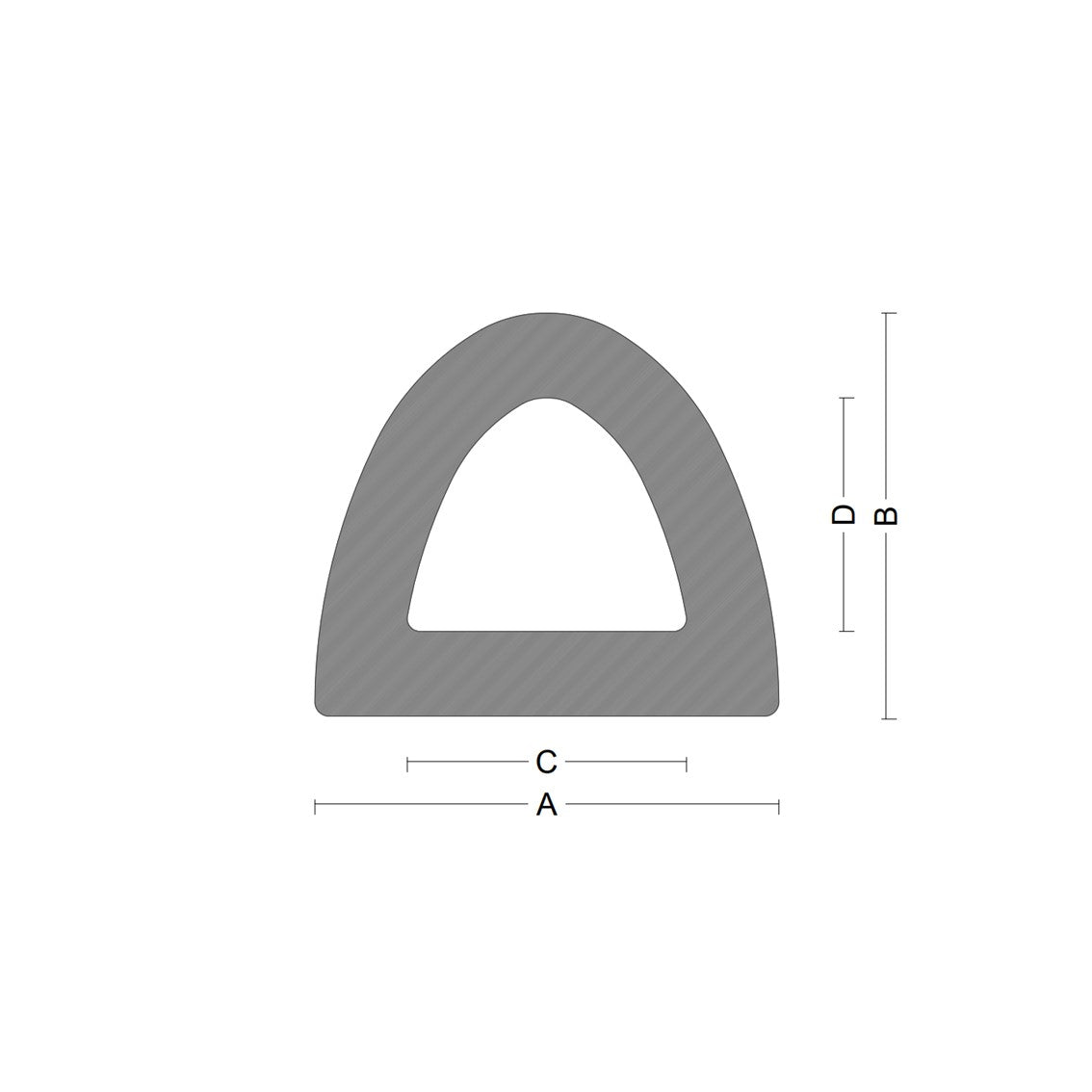

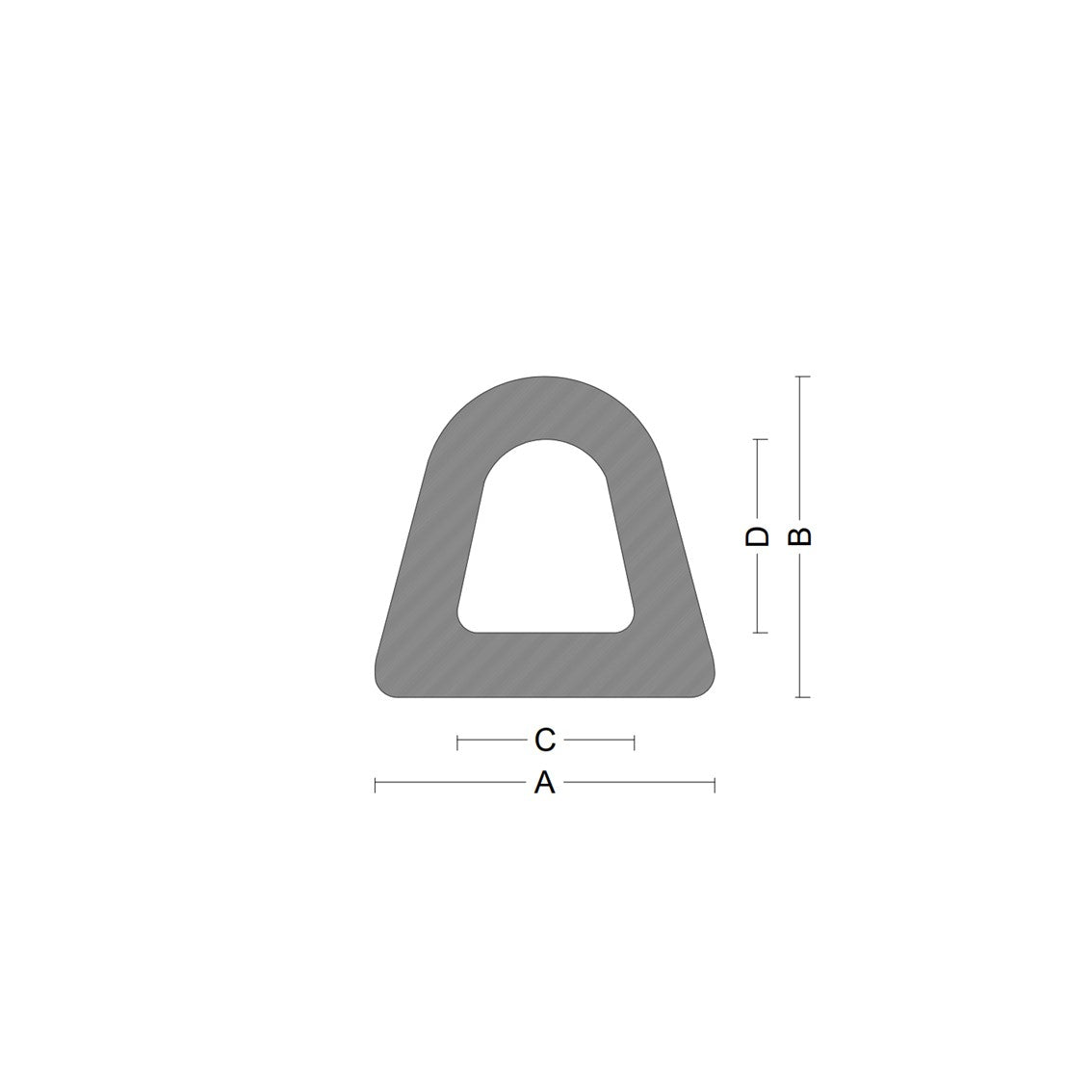

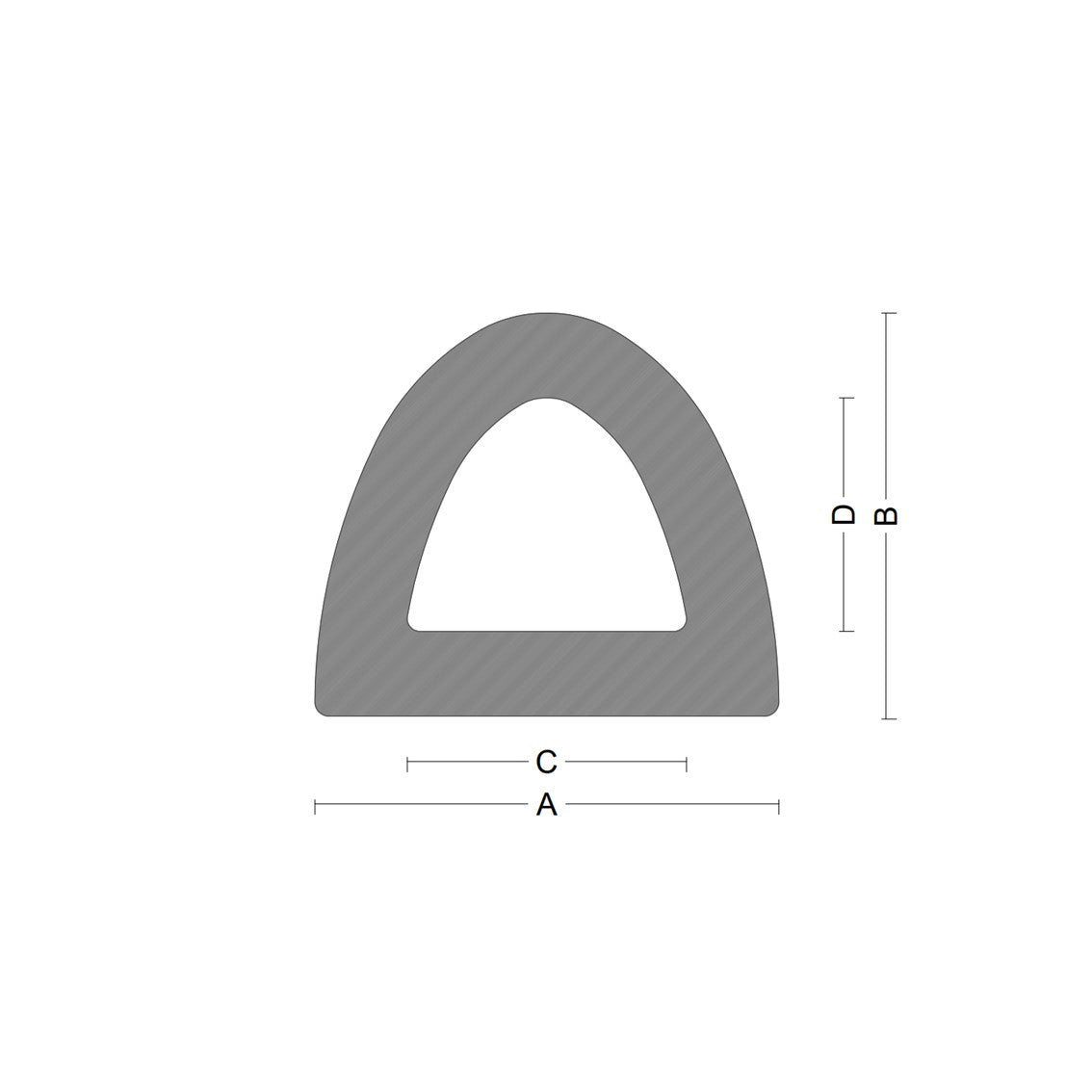

Delta fenders and Delta protection overview

Delta fenders are extruded rubber profiles used for perimeter protection and impact absorption on marine and industrial structures. Materials commonly offered include EPDM, SBR and TPE, and profiles are manufactured in a range of cross-sections and nominal sizes to suit different contact conditions. Options such as colour variants and pre-drilled bolt holes are available to support mechanical fixing and site installation. RuplaTec supplies a range of Delta fenders for shipyards, ports, construction and industrial applications.

Technical options for Delta profiles and installation

Delta profiles can be specified with differing shore hardness, wall thicknesses and mounting configurations according to application requirements. Pre-drilled bolt-hole options are frequently used to facilitate fixing to steel or concrete substrates. Drawings, material information or cut-to-length services may be available on request and can be helpful when preparing mounting details. For product selection, mechanical compatibility or specification advice contact our team; see the Delta fender rubber profiles collection for an overview of available types: Delta fender rubber profiles.

Applications for Delta rubbers and selection guidance

Typical uses include fendering on quays, pontoons, vessel hulls, loading edges and industrial equipment where Delta protection and damping are required. When specifying Delta rubbers consider expected loads, exposure to weather or chemicals, and intended attachment method. Our technical staff can help review application parameters and discuss suitable profile options.