Contact us

FAQ

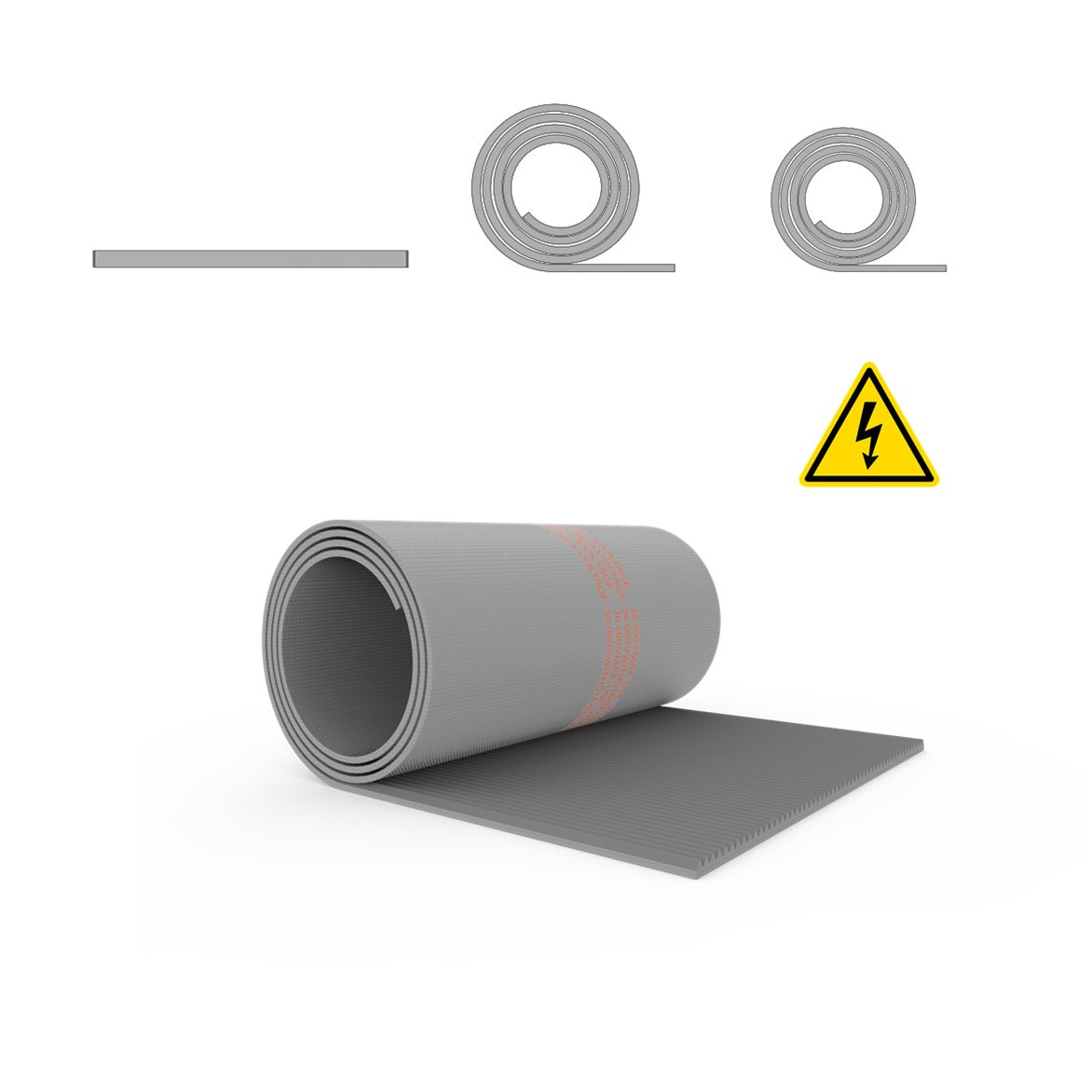

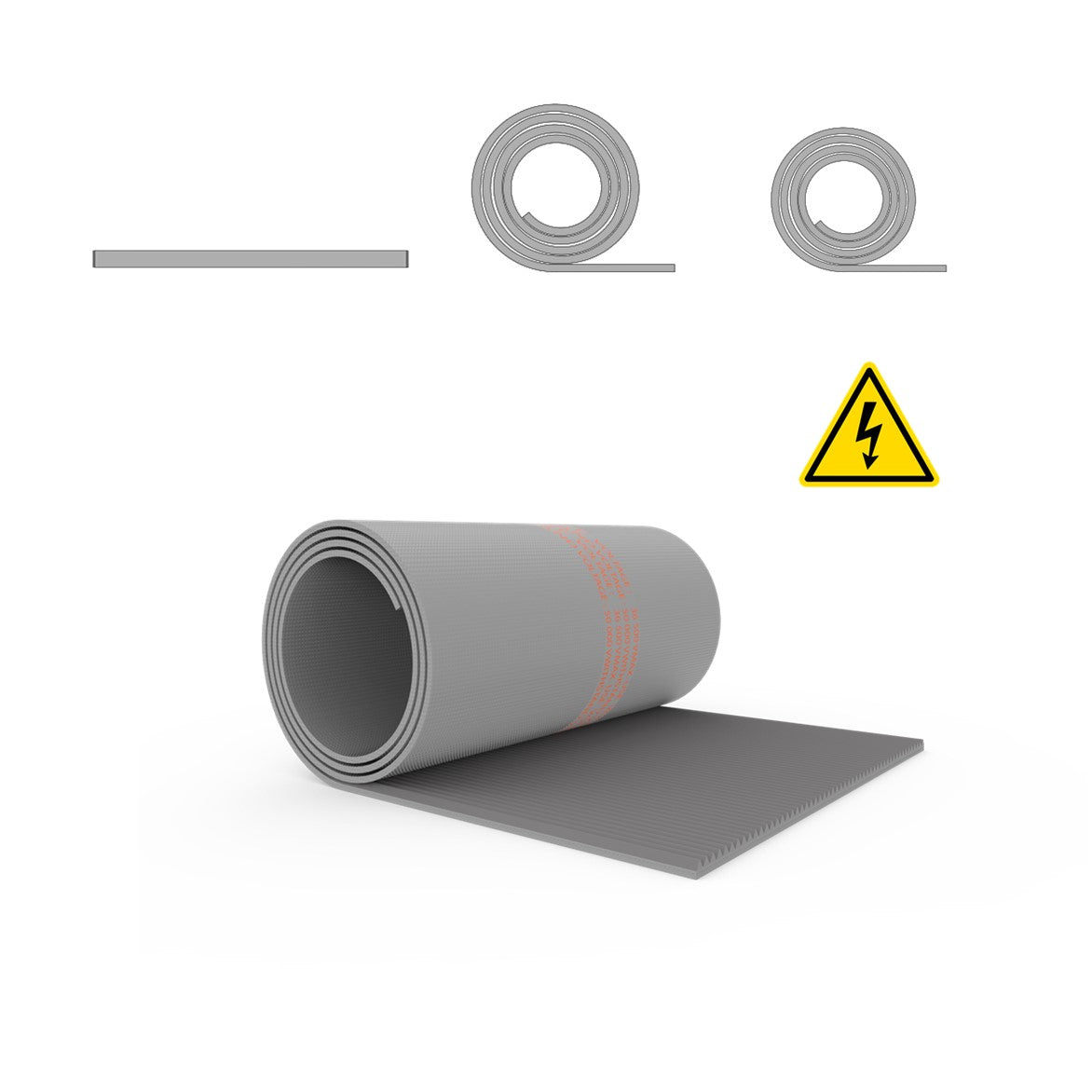

What is electrical safety matting?

Electrical safety matting, also known as electrical insulating mats, is designed to provide additional protection for people working near electrical equipment. The mats are usually made from rubber or PVC and are placed around switchboards, control panels, or high-voltage equipment areas.

Which standards apply to electrical safety matting?

Most insulating mats are manufactured and tested according to international standards such as IEC 61111 or BS EN 61111. These standards specify the electrical resistance, thickness, and testing methods required for mats used in different voltage environments.

Where is electrical safety matting commonly used?

These mats are often installed in front of switchboards, distribution boards, control panels, and other locations where electrical equipment is operated. They are also used in industrial environments, workshops, and areas where high-voltage systems are present.

Does electrical safety matting need regular inspection?

Yes. Mats should be checked regularly for wear, cuts, or contamination. Even though insulating mats are durable, physical damage or contamination with oil, moisture, or chemicals can affect their performance. It is recommended to follow the inspection and maintenance guidance provided by the manufacturer.

What factors should be considered when choosing electrical safety matting?

Key considerations include the voltage rating, the required standard (IEC 61111, BS EN 61111), the environment where the mat will be used (dry, wet, oily), and the thickness or width of the mat. For detailed specifications, always consult the official product documentation or brochure provided with the mats.