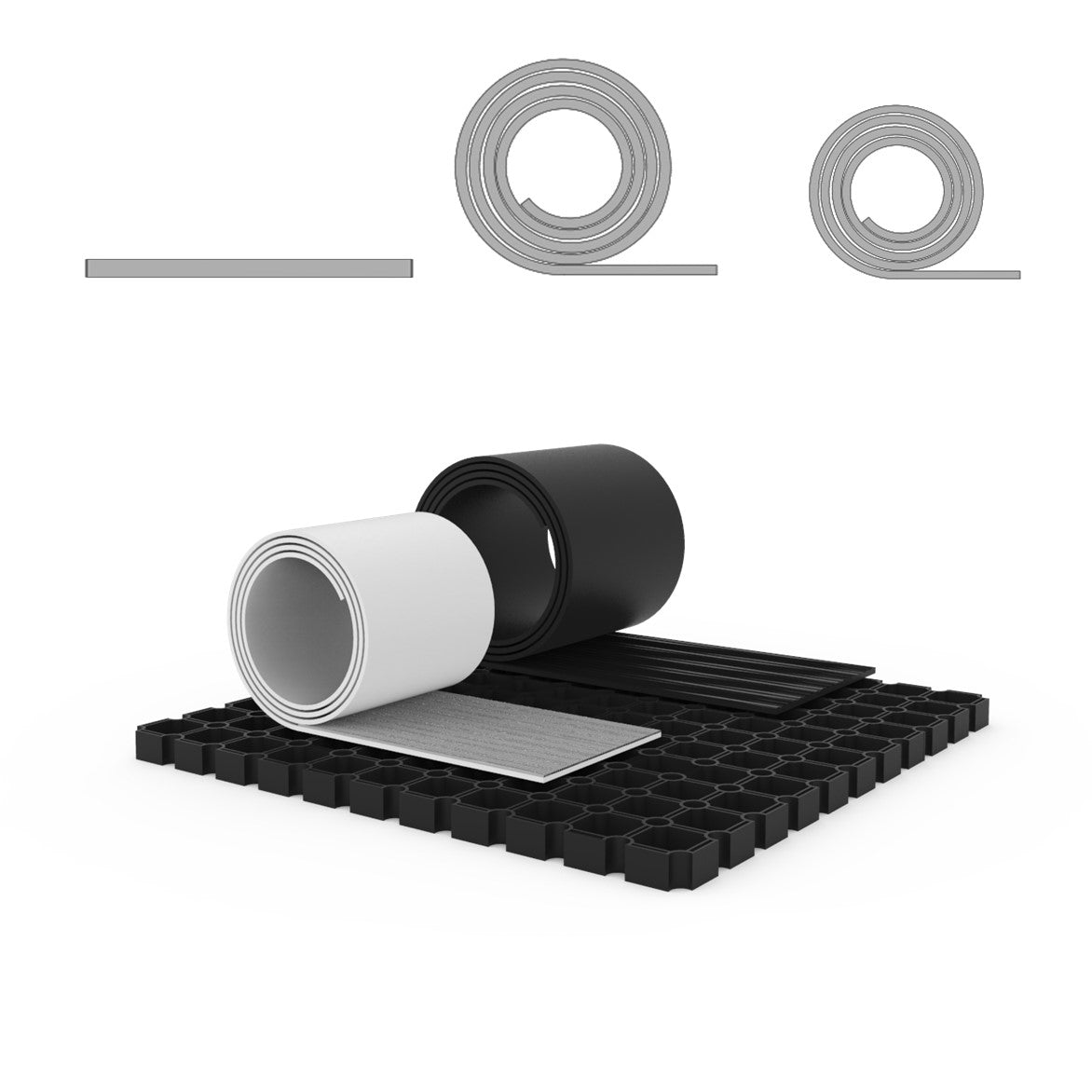

Rubber mat types and sizes

Rubber matting is supplied in a range of constructions to suit industrial and marine applications, including anti-fatigue standing mats, rubber rolls, heavy-duty mats and weather-resistant outdoor mats. Standard formats include sheet sizes, rolls and modular tiles, with thicknesses and surface profiles selected according to application. RuplaTec supplies technical rubber and plastic products and can offer guidance on matching a rubber mat to site conditions. See the broader rubber matting collection for typical formats and options: rubber matting collection.

Heavy duty rubber mat selection and industrial applications

Selection of a heavy duty mat or heavy duty rubber mat typically considers static and dynamic load, abrasion resistance, slip performance, chemical exposure and required drainage or anti-fatigue properties. Installation factors such as edge profiling, perimeter fixing and cut-to-size requirements are also relevant. Material compounds, durometer and textured finishes can affect wear and grip; specific compound performance data can be requested where available. Rubber mats are used in shipyards, workshops, loading areas and production lines where impact and mechanical stresses are common. For application-specific advice or to discuss custom sizes and tolerances, contact our team who can discuss typical industry practices and provide further technical information on request.