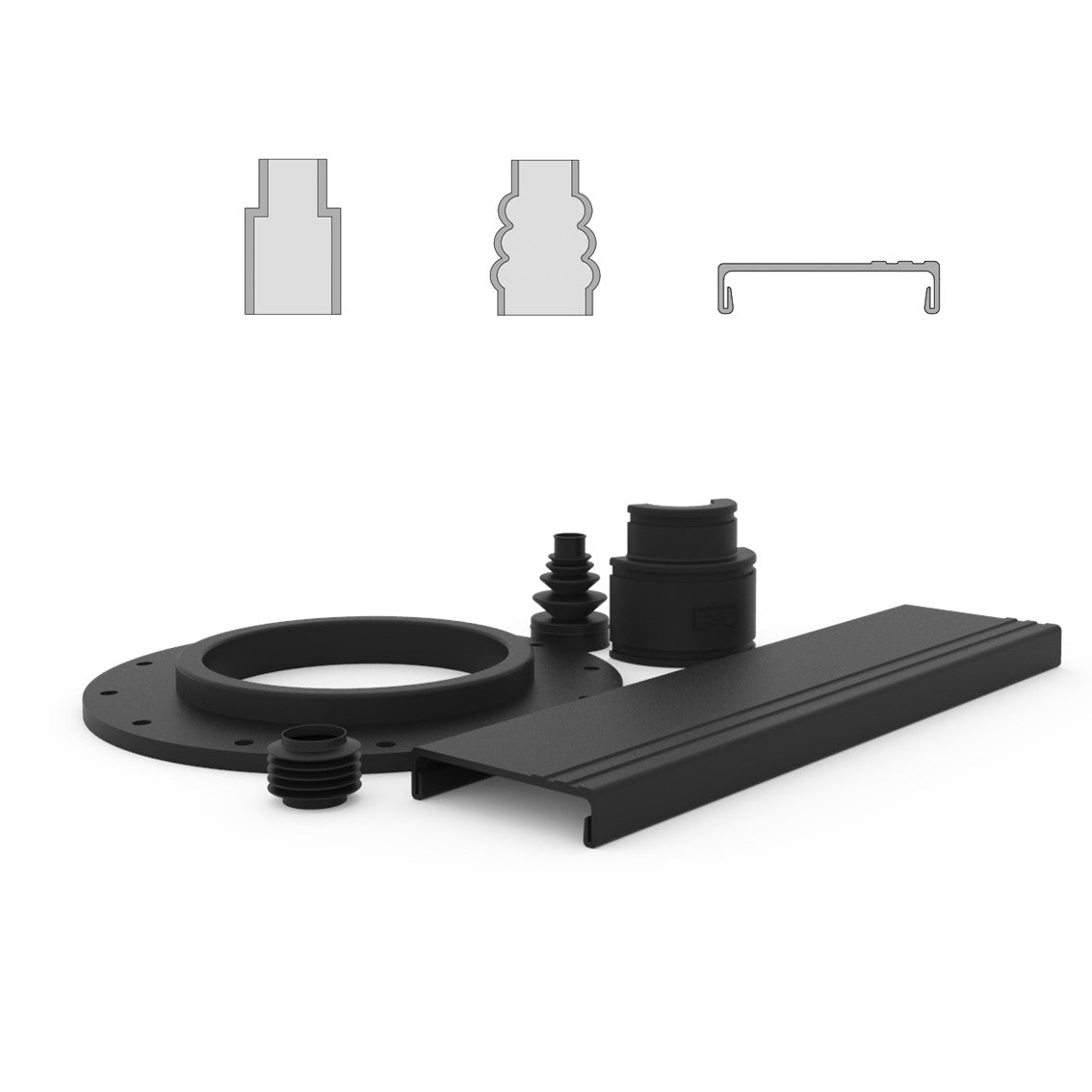

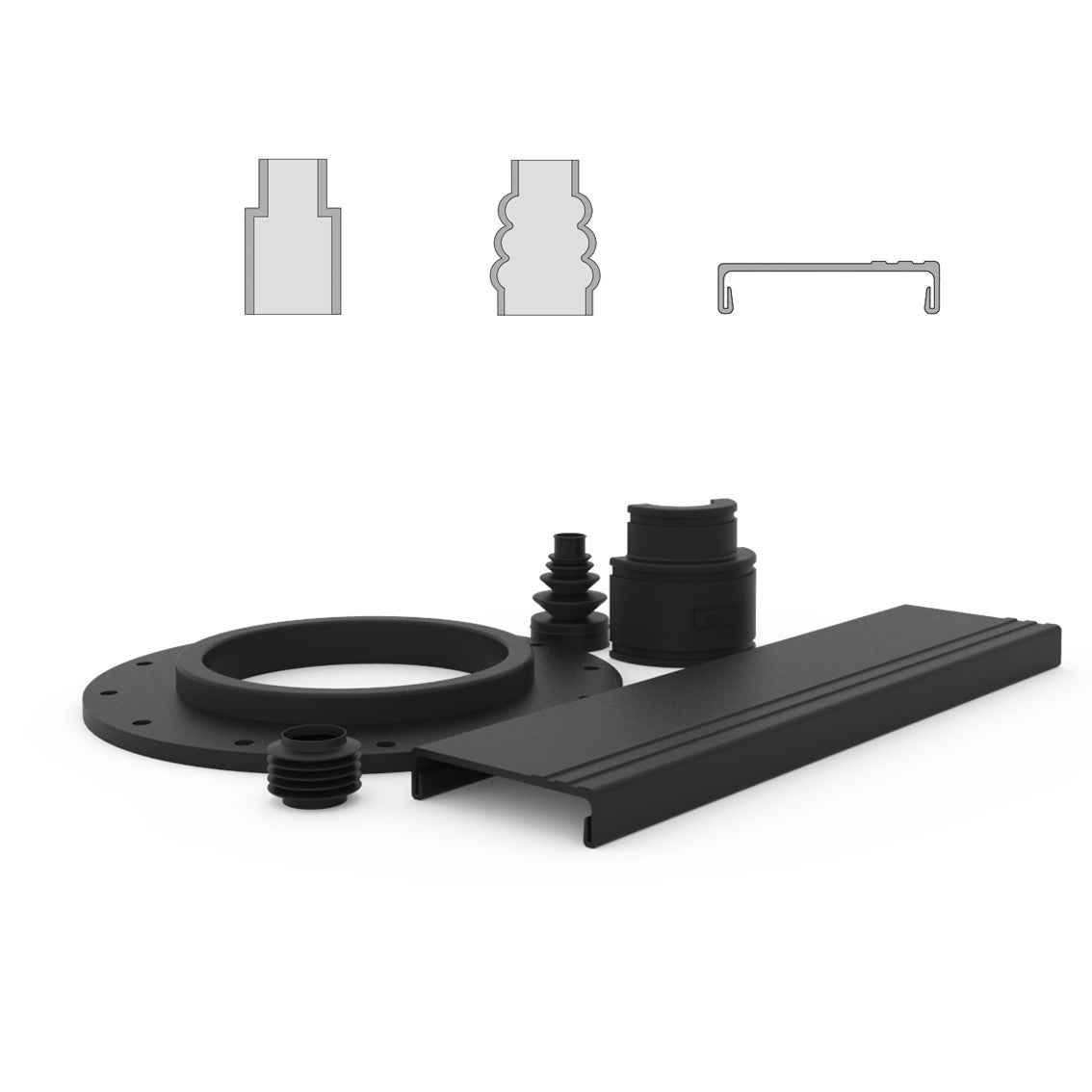

Industrial rubber mouldings: materials and typical applications

Industrial rubber mouldings are used for sealing, vibration isolation and wear protection across marine, construction, transport and manufacturing sectors. Profiles can be produced from a range of elastomers to address chemical resistance, temperature range and mechanical behaviour; material selection should be based on operating conditions and substance compatibility. Mouldings may be specified for static seals, dynamic seals, edge protection, anti‑vibration mounts and abrasive wear strips. RuplaTec supplies technical rubber and plastic products and can advise on material options and design trade-offs on request. For a representative selection of standard and bespoke options see industrial rubber mouldings.

Design, custom profiles and procurement guidance

Design considerations include cross‑section geometry, tolerances, shore hardness and surface finish. Manufacturing routes such as extrusion, compression or injection moulding may be selected according to profile complexity and order quantity; tooling and secondary operations like trimming, vulcanising or bonding may be required for assemblies. Where precise fit is important, drawings, measured samples or CAD profiles can aid specification; dimensional tolerances and testing requirements can be discussed with our technical team. Contact our team for advice on selecting elastomers, specifying profiles or defining quality checks relevant to industrial applications.