Rubber mouldings

RuplaTec is a European expert in rubber mouldings, with more than 60 years of experience in rubber and plastic materials.This expertise is rooted in long-term involvement in industrial applications where material performance and reliability are essential.

Collection: Rubber mouldings

-

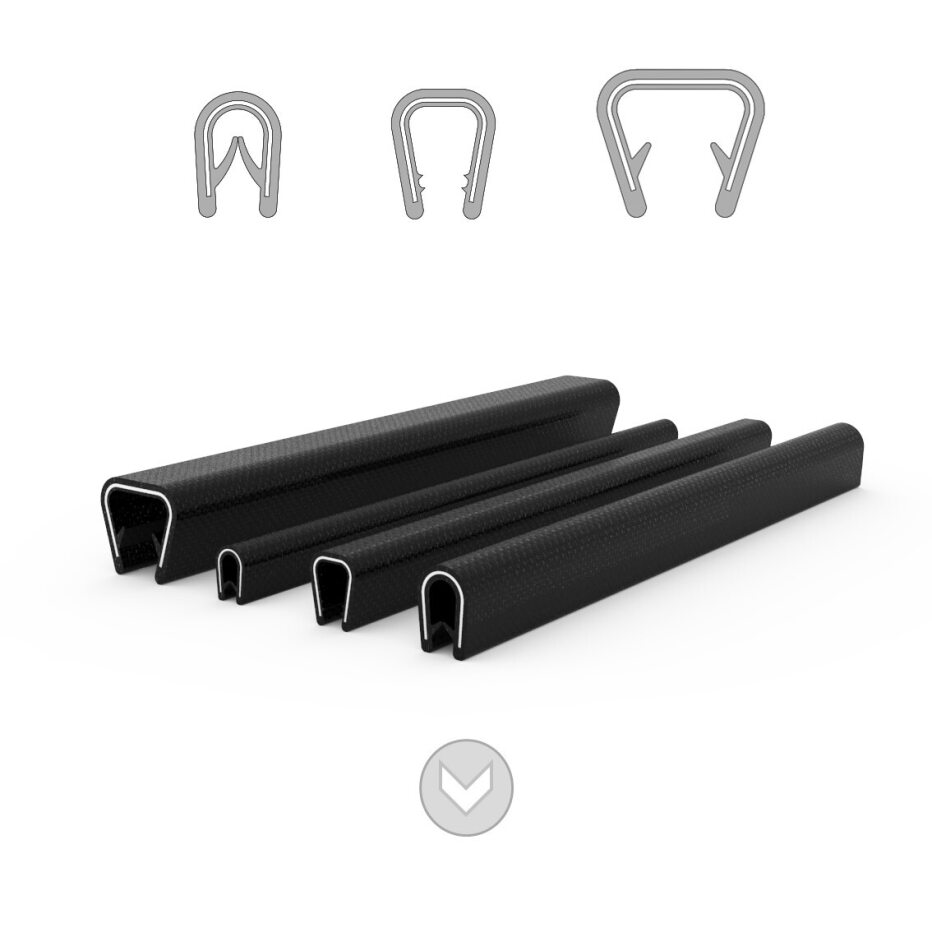

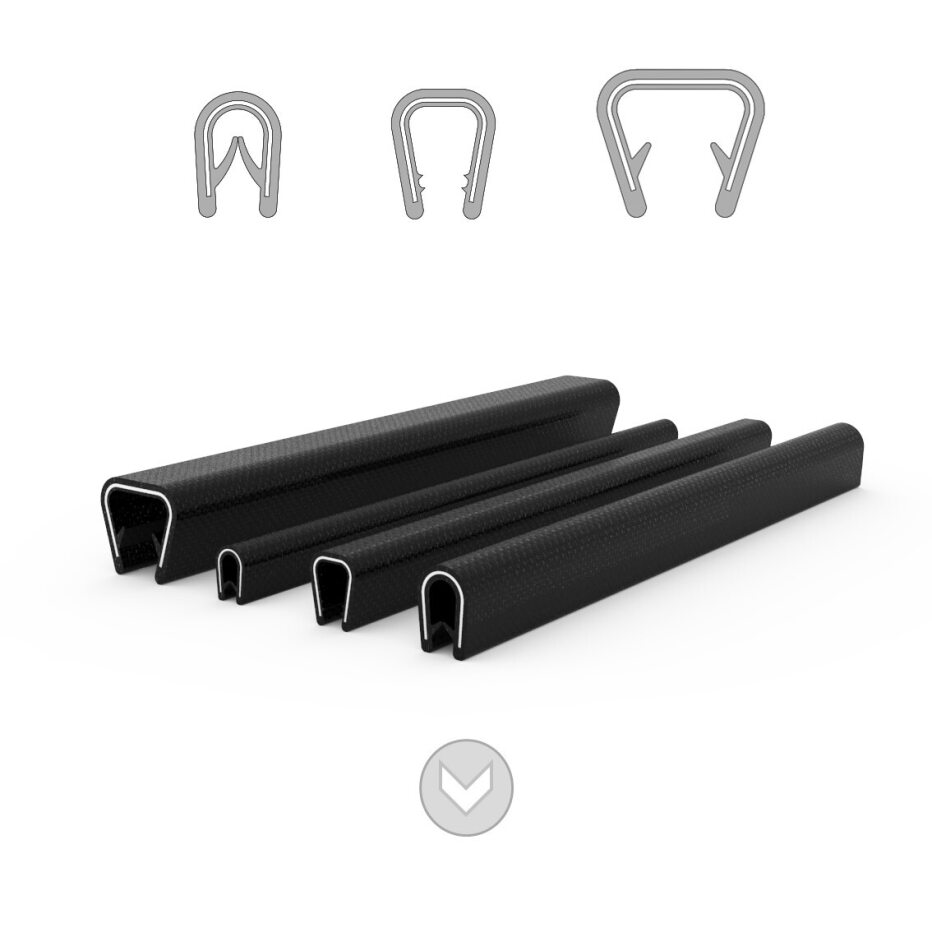

Rubber Step Caps

Regular price €0,00 EURRegular priceUnit price / per -

Custom rubber rings

Regular price €0,01 EURRegular priceUnit price / per -

Rubber mouldings

Regular price €0,01 EURRegular priceUnit price / per

Customized and specialized Rubber mouldings options

If you can't find what you're looking for, don't worry! We have the capability to manufacture Rubber mouldings in practically any design you require.

What are rubber mouldings

Rubber mouldings are shaped rubber components produced by moulding rubber compounds into specific forms. This manufacturing process allows complex geometries and consistent shapes to be created for functional use.

Rubber mouldings are made from various rubber materials, depending on the application requirements, and are designed to provide sealing, protection or mechanical functionality.

What are rubber mouldings used for

Rubber mouldings are commonly used in applications where shaped rubber parts are required to fit specific components or assemblies. Typical uses include seals, covers, buffers, feet and protective elements in industrial equipment.

Because moulded rubber parts can be produced to precise shapes, they are often selected for applications where standard extruded profiles or flat sheets are not suitable.

Are rubber mouldings suitable for industrial applications

Yes, rubber mouldings are widely used in industrial applications due to their versatility and functional reliability. The moulding process allows the material to perform consistently under mechanical stress.

Depending on the rubber compound used, mouldings can provide properties such as flexibility, impact absorption or environmental resistance.

What affects the performance of rubber mouldings

The performance of rubber mouldings depends on factors such as the rubber material, mould design and operating conditions. These factors influence durability, fit and functional behaviour over time.

Material selection should therefore be based on the application requirements and the environment in which the moulded part will be used.

Products similar to Rubber mouldings

-

Rubber extrusions

What are rubber extrusions Rubber extrusions are rubber profiles that are produced...

-

Custom rubber extrusions

What are custom rubber extrusions Custom rubber extrusions are rubber profiles that...

-

Flat gaskets

What are flat gaskets? Flat gaskets are sealing components used to create...

-

Rubber edge trim seals

What are rubber edge trim seals Rubber edge trim seals are flexible...

-

Edge trims PVC

What are edge trims An edge trim profile is used to finish...

-

Extensive inventory

Explore our extensive range of Rubber mouldings, readily available for fast delivery, thanks to our well-maintained stock, ensuring fast fulfillment of your orders.

-

Bespoke custom types

We have the capacity to manufacture Rubber mouldings according to client drawings or specifications, utilizing a wide range of materials to meet your needs.

-

Fast delivery in the EU & UK

Our strategic location close to the Port of Rotterdam, enables us to provide rapid and efficient deliveries to customers across Europe.

-

Competitively priced products

With our manufacturing expertise and advanced facilities, we provide quality products at competitive prices. Request a free quote today.

-

+ 50 years of industry experience

With over 50 years of industry experience, our experienced team is ready to assist you. Feel free to contact us with any questions about our products or services.