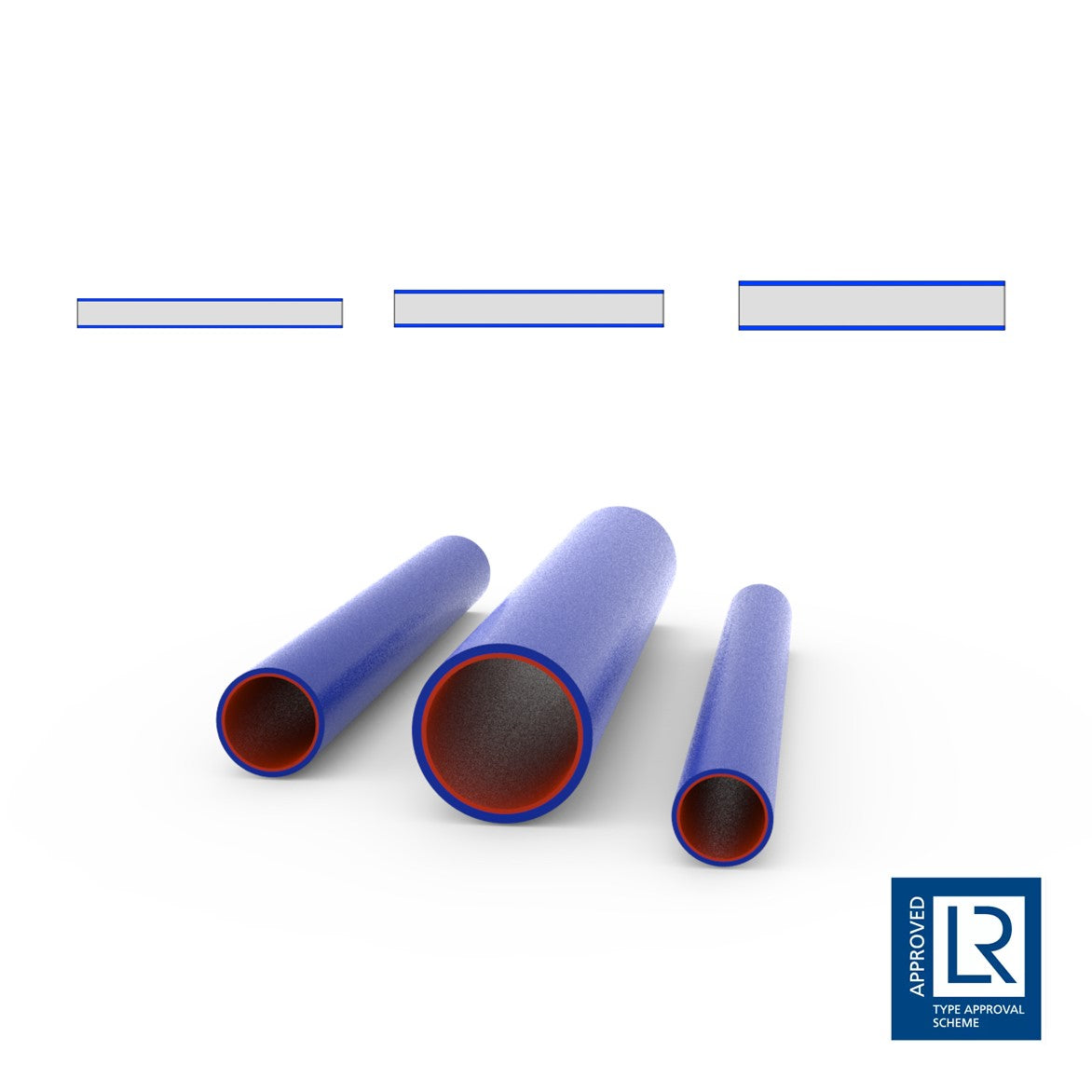

Silicone hoses - Straight lengths and size options

Straight silicone hoses supplied in one-metre lengths are available for a range of industrial and marine applications. Sizes from 6 mm to 45 mm are available and, in many cases, offered with a 3‑ply polyester reinforced wall; specific construction and wall thickness vary by size and grade. These silicone hoses are commonly specified for flexible fluid and air transfer, coolant lines, and where chemical and temperature resistance characteristics of silicone are appropriate. Material compatibility, pressure rating and temperature range depend on the exact compound and reinforcement chosen and should be reviewed against the intended application.

Technical queries, options and ordering

Options such as alternative silicone grades, custom lengths, fittings, hose clamps and assembly services can be discussed with our team; technical drawings or application details may be requested to confirm suitability. For customers looking for a broader selection, see the full Silicone hoses collection for available sizes and reinforcement types. RuplaTec supplies silicone hoses to shipyards, construction firms, transport and logistics companies and manufacturers; contact our team for application advice, compatibility checks or to request further product data.