Product overview

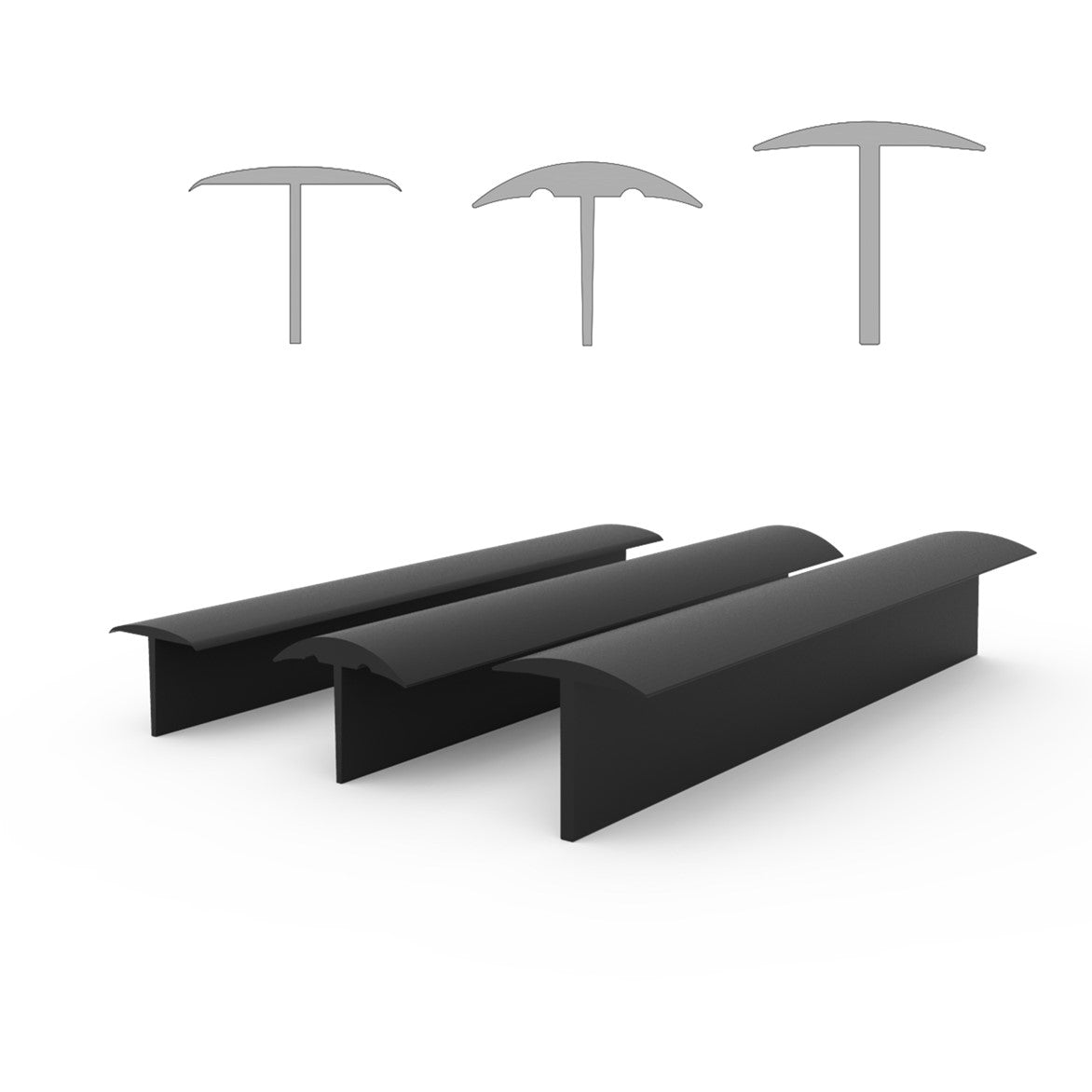

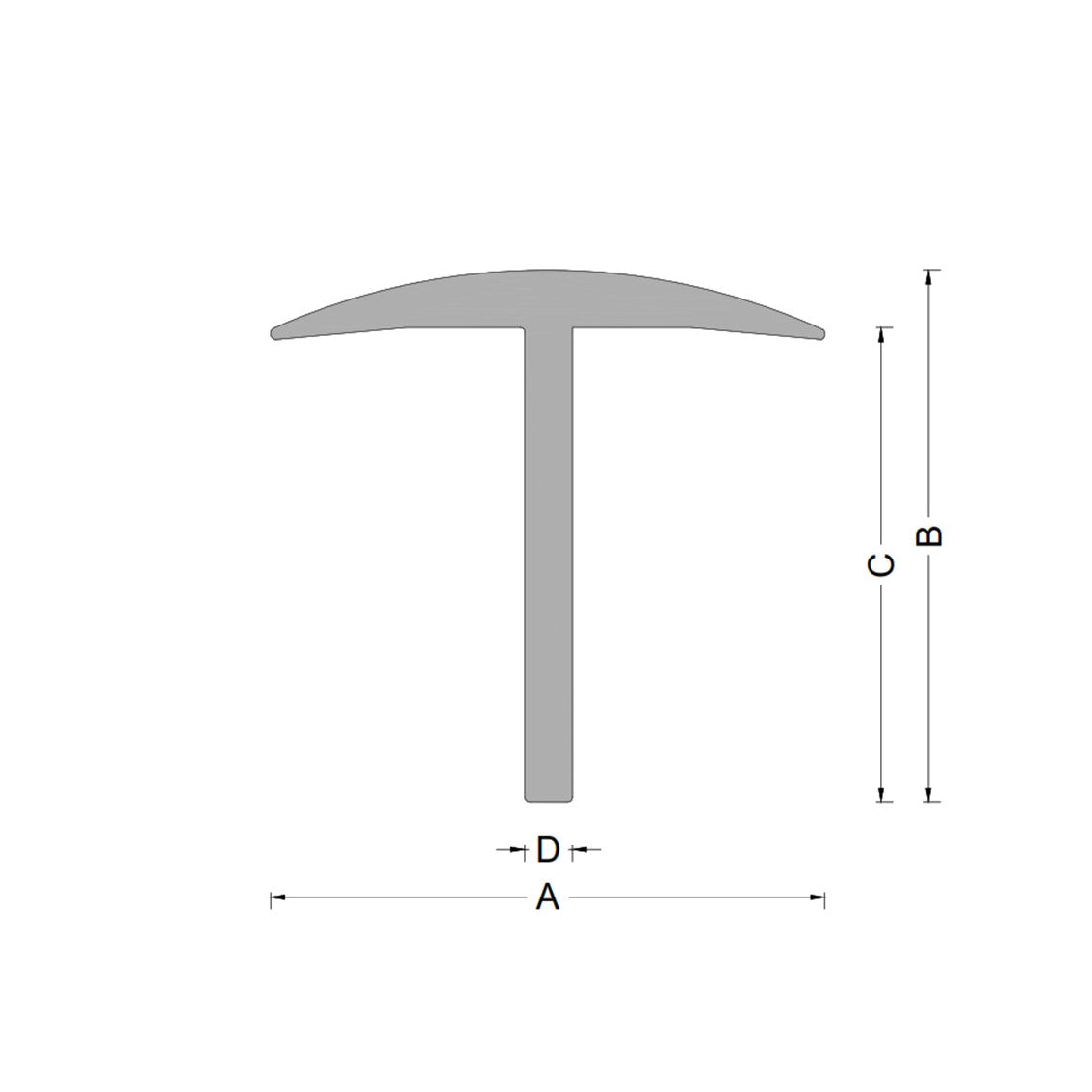

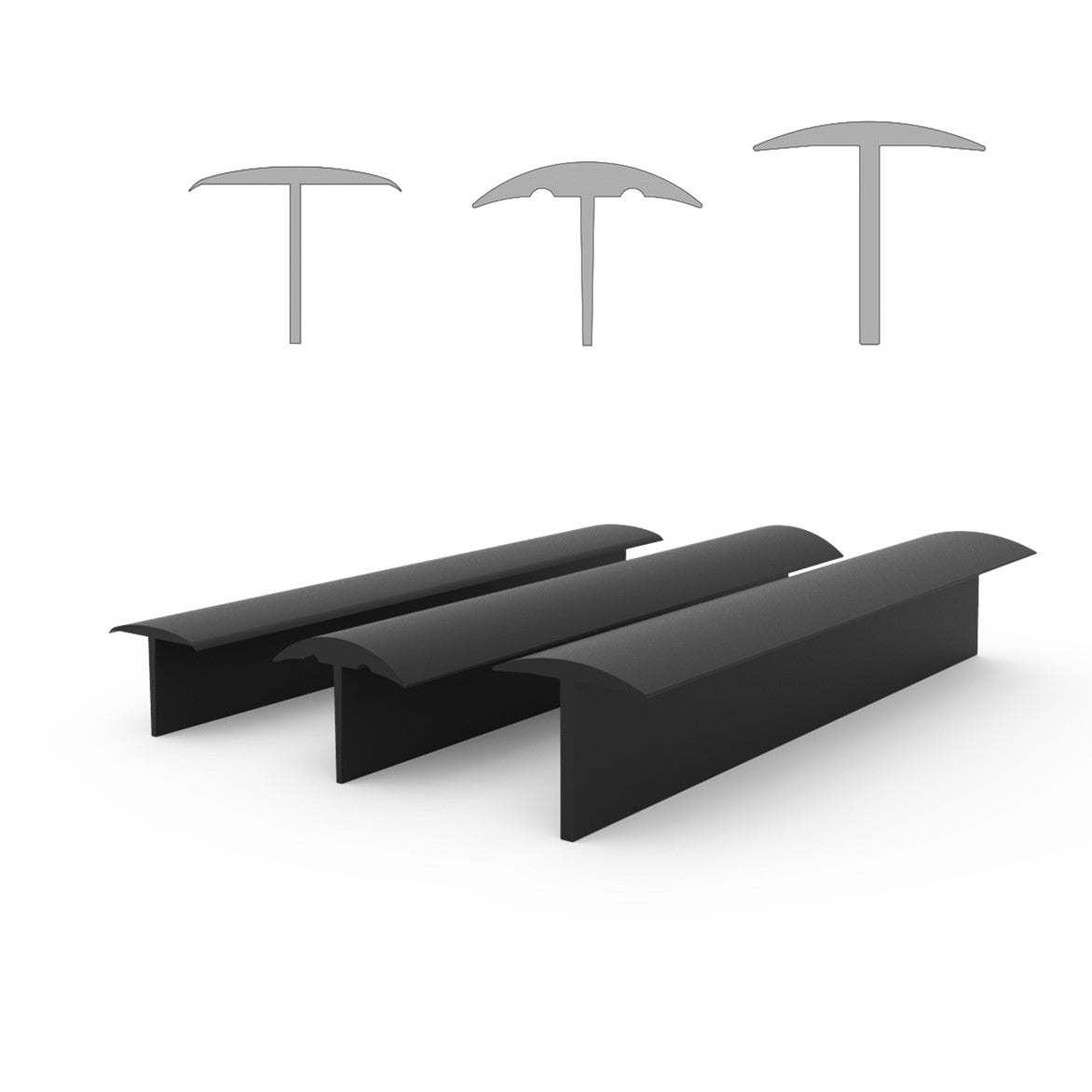

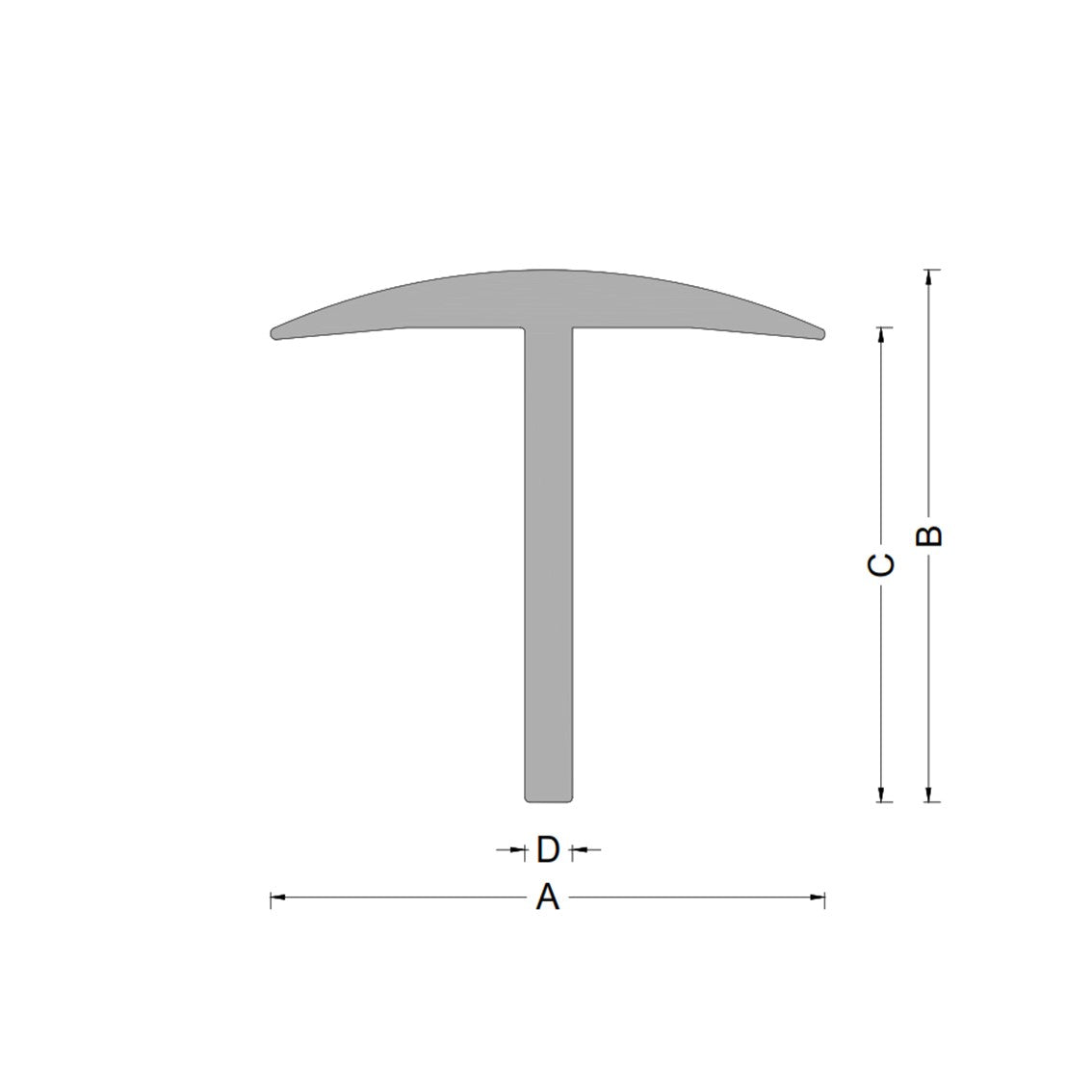

RuplaTec supplies a range of weighbridge rubbers in T profiles to suit different weighbridge designs. These Rubber T profiles are intended to limit the ingress of grit and dirt into the weighbridge structure and to provide a replaceable wear interface where moving or exposed elements meet the deck. Available in multiple cross‑section shapes and sizes, the range covers standard and bespoke requirements.

Applications

T profiles are typically used at deck edges, access points and joints on static and pit‑style weighbridges. Their primary function is to reduce particulate ingress and to protect adjacent materials from abrasion. Selection should reflect the site environment, expected traffic patterns and compatibility with surrounding materials.

Selection and variants

We offer standard rubber extrusions as well as custom options. For catalogue items see the weighbridge rubbers collection or request tailored sections via our custom extrusions page. When choosing a Rubber T profile, consider section geometry, shore hardness and material compound compatibility; our team can advise on making these choices based on observed service conditions.

Installation and maintenance

Installation is typically by mechanical fixings or adhesive bonding compatible with the chosen compound. Routine inspection for wear, ingress and adhesion is recommended to determine replacement intervals. Replacement of worn profiles prevents accelerated deterioration of the weighbridge structure.

Support

For technical queries or assistance with selection, RuplaTec’s team can provide application guidance and discuss custom tooling options.