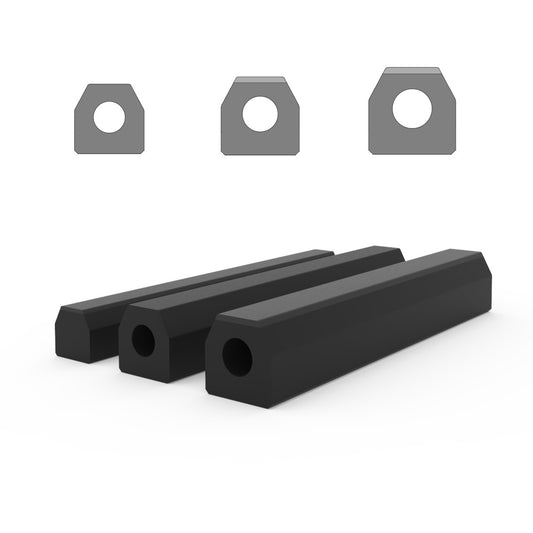

Composite rubber & UHMWPE fender blocks

We have all heights of HDPE sheets and strips in stock. Didn't find what you are looking for? We can manufacture practically any shape and size of HDPE sheets and strips. Please don't hesitate to contact us to discuss any projects or inquiries.

Collection: Composite rubber & UHMWPE fender blocks

-

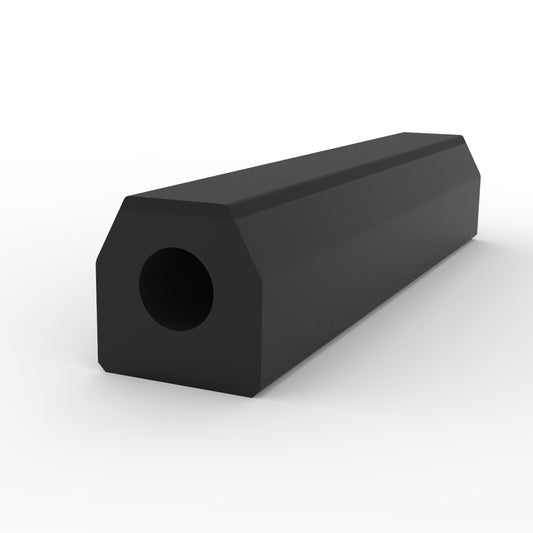

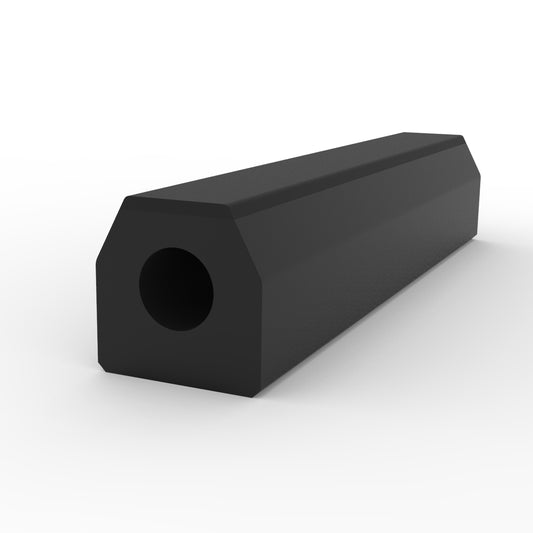

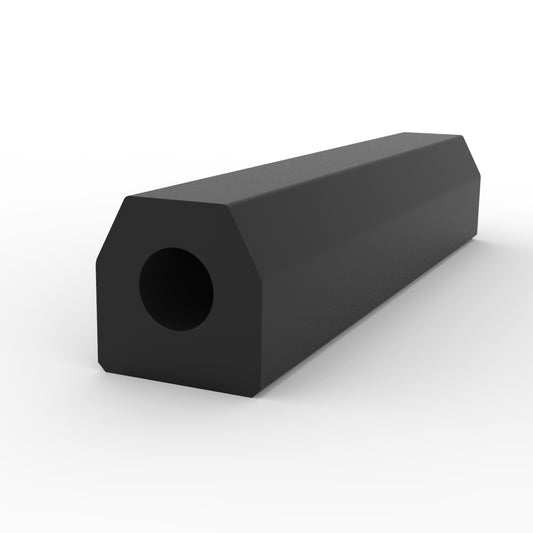

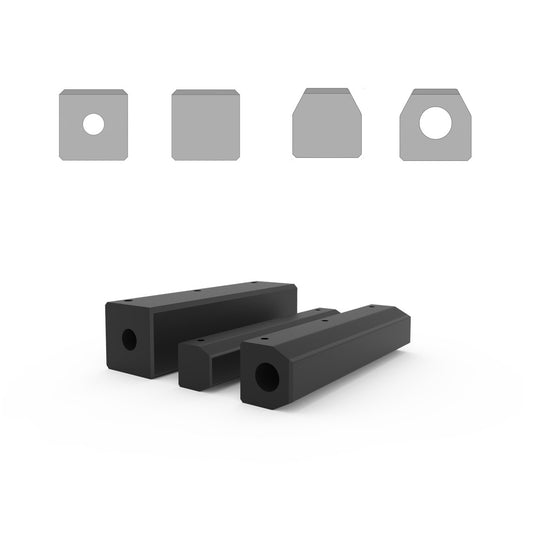

Trapezium fenders

Regular price €0,01 EURRegular priceUnit price / per -

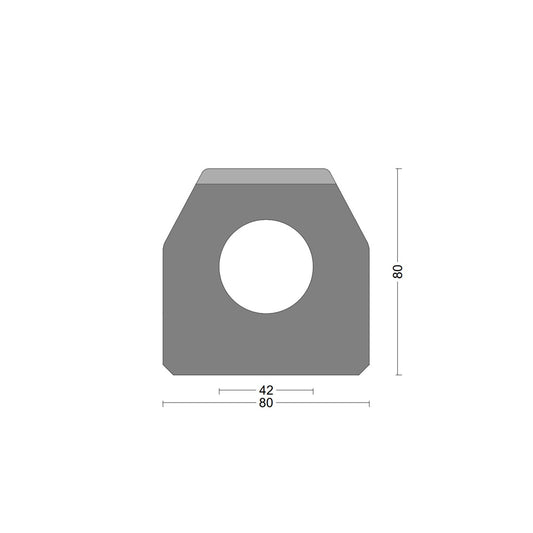

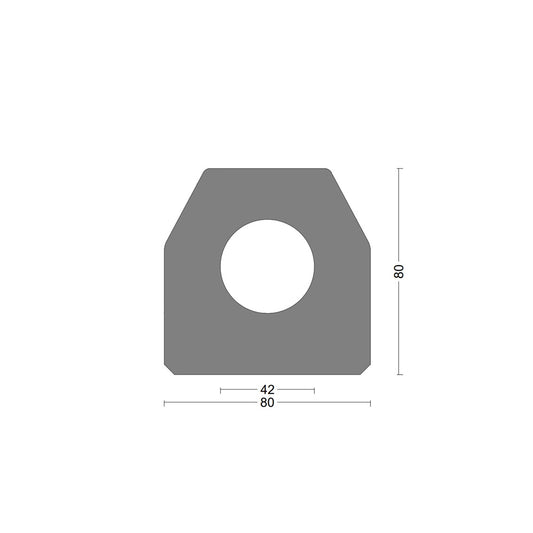

CF-C trap. Composite fender 80x80mm o-bore 42

Regular price €0,01 EURRegular priceUnit price / per -

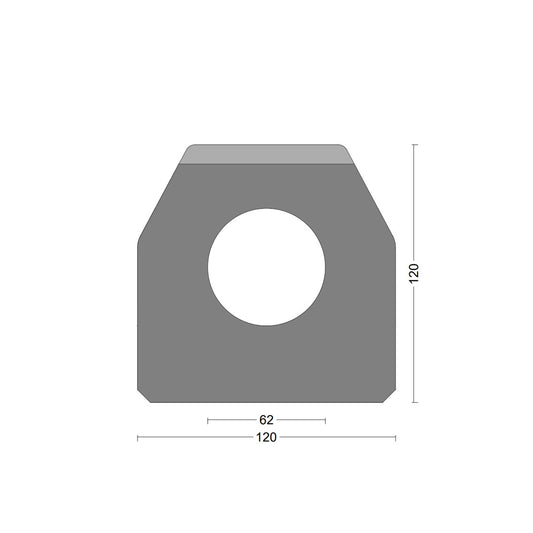

CF-C trap. Composite fender 120x120mm o-bore 62

Regular price €0,01 EURRegular priceUnit price / per -

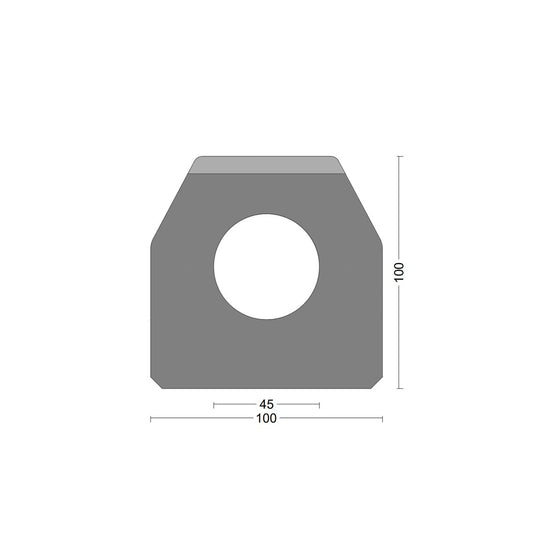

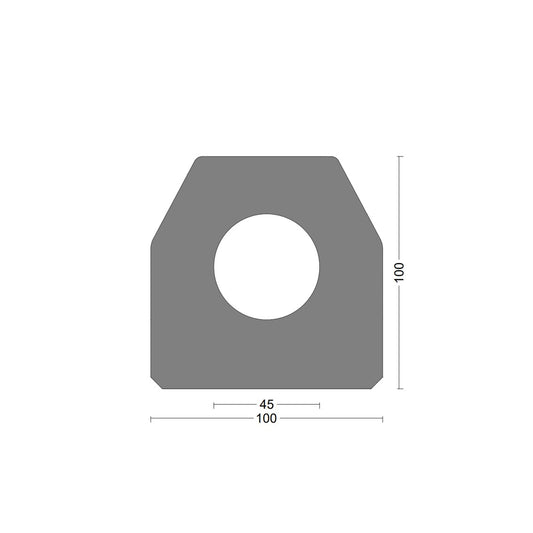

CF-C trap. Composite fender 100x100mm o-bore 45

Regular price €0,01 EURRegular priceUnit price / per -

CF trap fender 80x80mm o-bore 42

Regular price €0,01 EURRegular priceUnit price / per -

CF trap fender 100x100mm o-bore 45

Regular price €0,01 EURRegular priceUnit price / per -

Composite rubber & UHMWPE fender blocks

Regular price €0,01 EURRegular priceUnit price / per

Customized and specialized Composite rubber & UHMWPE fender blocks options

If you can't find what you're looking for, don't worry! We have the capability to manufacture Composite rubber & UHMWPE fender blocks in practically any design you require.

-

Extensive inventory

Explore our extensive range of Composite rubber & UHMWPE fender blocks, readily available for fast delivery, thanks to our well-maintained stock, ensuring fast fulfillment of your orders.

-

Bespoke custom types

We have the capacity to manufacture Composite rubber & UHMWPE fender blocks according to client drawings or specifications, utilizing a wide range of materials to meet your needs.

-

Fast delivery in the EU & UK

Our strategic location close to the Port of Rotterdam, enables us to provide rapid and efficient deliveries to customers across Europe.

-

Competitively priced products

With our manufacturing expertise and advanced facilities, we provide quality products at competitive prices. Request a free quote today.

-

+ 50 years of industry experience

With over 50 years of industry experience, our experienced team is ready to assist you. Feel free to contact us with any questions about our products or services.

High Density Polyethylene (HDPE) specifiactions

HDPE (High-Density Polyethylene) is a strong and versatile plastic with excellent chemical resistance and very good mechanical properties. It is widely used in applications where durability, impact resistance and long-term reliability are required. HDPE performs well in chemically aggressive environments and retains its mechanical properties during use. However, it is not suitable for high-temperature applications.

Temperature range: −50 °C to +80 °C

At RuplaTec, HDPE is available as HDPE sheets and HDPE strips, supplied in standard sizes or fully custom-made.

Properties of High-Density Polyethylene (HDPE)

| Chemical resistance | Excellent |

| Impact strength | High |

| Durability | High, long service life |

| Weather resistance | Good |

| Ozone resistance | Good |

| Tensile strength | High |

| Abrasion & tear resistance | Good |

| Moisture absorption | Very low |

| Electrical insulation | Good |

| Mechanical stability | Retains properties during use |

| Maximum continuous temperature | 80 °C |

Applications of High-Density Polyethylene (HDPE)

- Pipes and fittings: Chemically resistant piping systems for industrial and residential use.

- Containers and tanks: Safe storage of chemicals, oils and liquids.

- Cutting boards: Food-safe, low moisture absorption and easy to clean.

- Geomembranes: Landfill liners, pond liners and environmental protection.

- Packaging: Blow-molded bottles and containers for chemicals and detergents.

- Wear strips and pads: Protection against abrasion and mechanical wear.

- Playground equipment: Durable and UV-resistant for outdoor use.

- Industrial components: Machine parts, tanks and storage bins.

- Marine applications: Docks, buoys and boat components due to water resistance.

Custom CNC machining

We can CNC-cut HDPE into virtually any shape, including strips, gaskets and rings. Contact our team to discuss your project or request a quotation.