What are custom mica gaskets

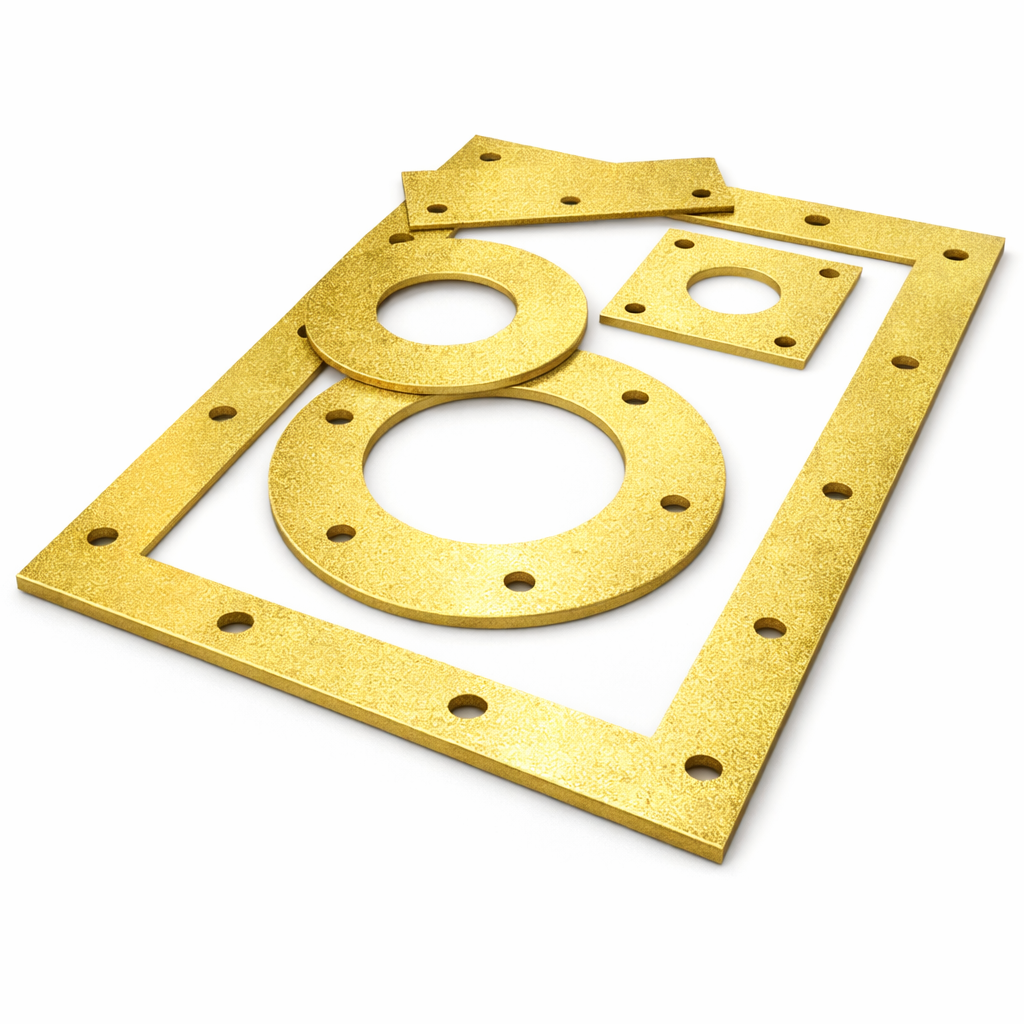

Custom mica gaskets are industrial sealing components manufactured according to specific dimensions or application requirements using mica-based materials. They are used where standard gasket formats are not suitable and where high temperature resistance is a critical factor.

These gaskets are commonly produced from micalite or micanite constructions, in which mica layers are combined with binders or reinforcement to provide structural stability while maintaining thermal resistance.

When do you need custom mica gaskets

Custom mica gaskets are required in sealing applications exposed to extreme temperatures, hot gases or thermal cycling, where conventional fiber or rubber gaskets would degrade or fail. They are typically selected for static sealing applications where elasticity is less important than heat resistance.

Depending on the operating conditions, different mica types such as phlogopite or muscovite mica may be used to suit the thermal and mechanical demands of the application.

Applications of custom mica gaskets

Custom mica gaskets are used in furnaces, boilers, exhaust systems, heat shields and high-temperature flange connections. They are applied in industries such as power generation, petrochemical processing, metallurgy and heavy industrial manufacturing.

These gaskets can be produced in a wide range of shapes and sizes to match specific sealing surfaces, making custom mica gaskets suitable for both OEM installations and maintenance or retrofit applications.