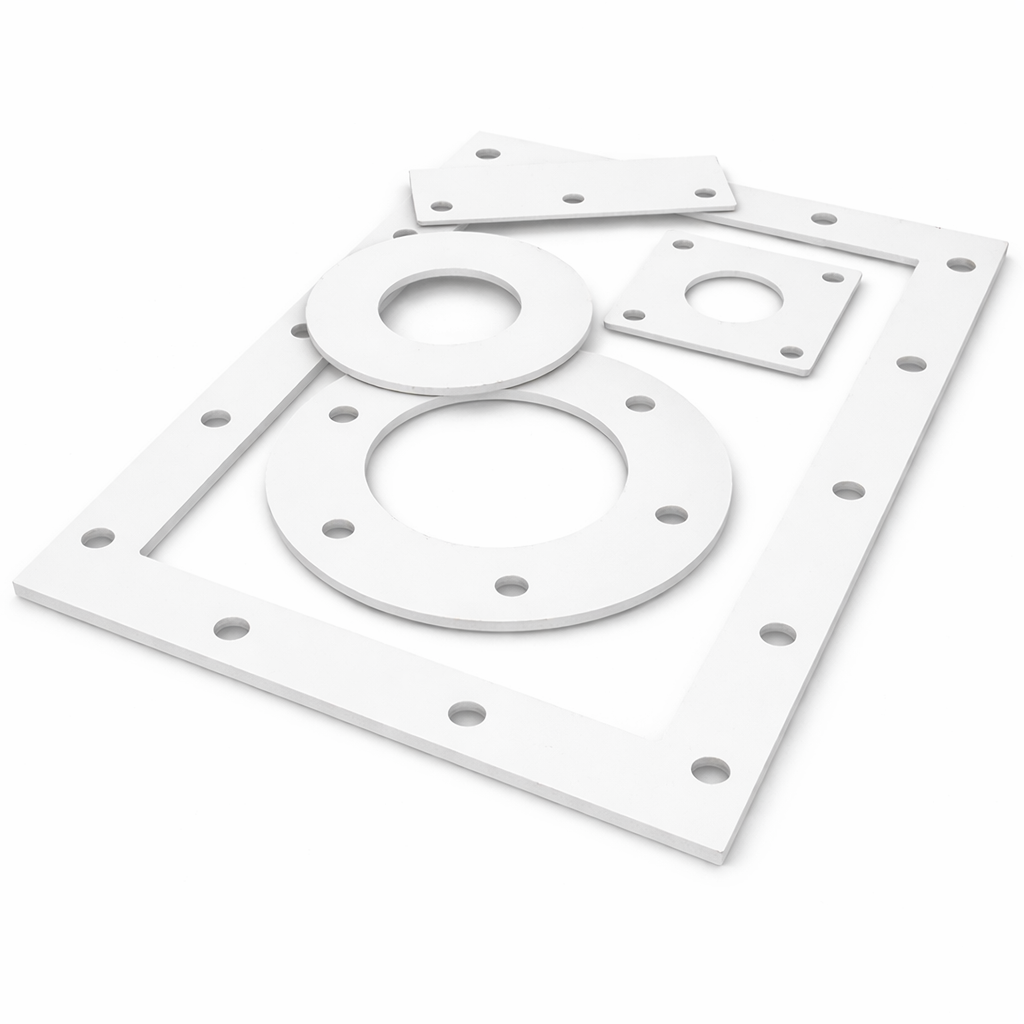

Applications of Custom PTFE gaskets

Custom PTFE gaskets are commonly used as static seals in chemical processing, pharmaceutical, food and beverage, semiconductor and petrochemical equipment, as well as in pump housings, valves, heat exchangers and flanged connections where chemical resistance and low contamination risk are required. Their resistance to aggressive media, low surface energy and broad service temperature range make them suitable for Teflon-lined vessels and high-purity systems where low friction and low permeability are important.

PTFE is often chosen for its inertness and low friction, but it can exhibit limited elastic recovery and creep under sustained load, so it may be less suitable where large flange movement, dynamic sealing with extrusion risk or abrasive conditions occur. Material options for ptfe may include filled or reinforced variants depending on application demands.