What are PVC edge trim profiles

PVC edge trim profiles are profiles manufactured from polyvinyl chloride (PVC) and are designed to be fitted over exposed edges of panels, sheets or components. They are used to protect edges, improve safety and provide a clean, finished appearance in technical and industrial applications.

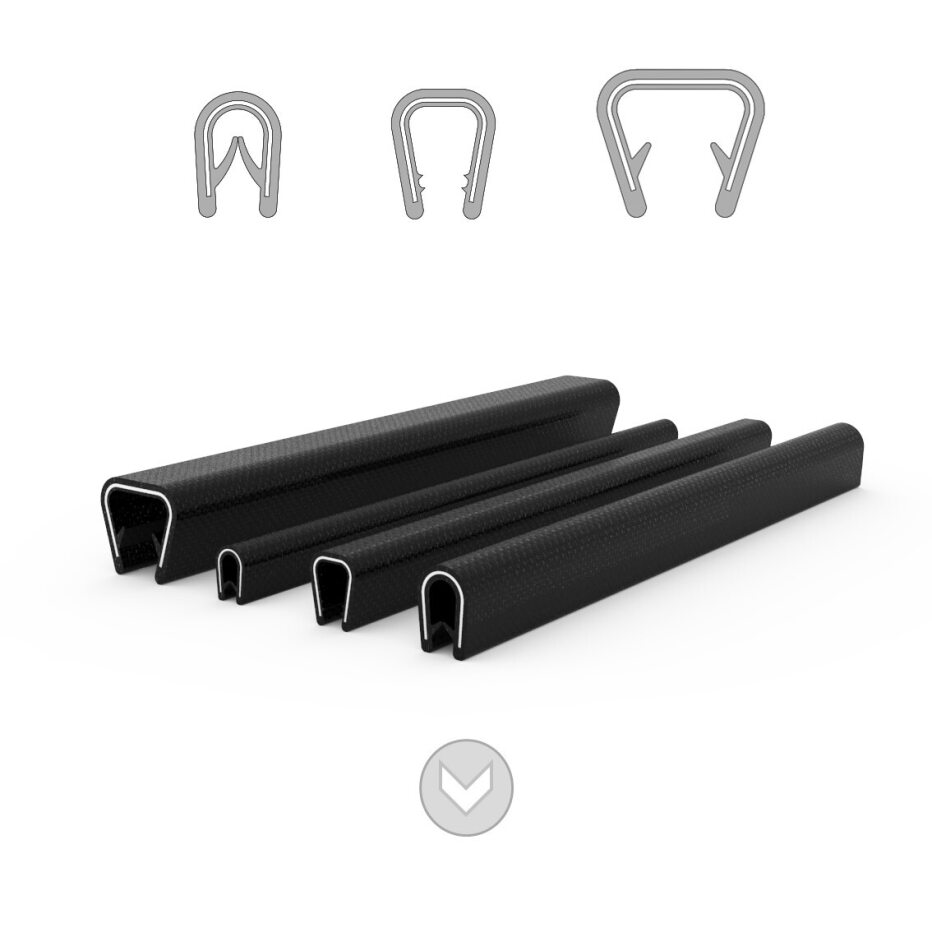

PVC edge trim profiles are typically supplied in various shapes and sizes to accommodate different edge thicknesses. Due to their shape stability, they provide consistent edge protection while maintaining a neat visual finish.

When to use PVC edge trim

PVC edge trim is used when exposed edges require protection against damage, wear or sharp contact. This is commonly the case with metal sheets, panels or cut edges where safety and durability are important.

These profiles are often applied as self-gripping edge trims, allowing them to be pressed onto the edge without the need for additional fasteners or adhesives in many applications.

Applications of PVC edge trim profiles

PVC edge trim profiles are used in a wide range of industrial and technical applications. Typical uses include edge protection for metal sheets, panels, enclosures and housings, as well as finishing profiles for exposed edges in equipment and installations.

Thanks to the dimensional stability of PVC, these edge trim profiles are suitable for permanent installations where consistent edge protection and a clean appearance are required over time.