Electrical safety matting — voltage ratings and standards

Matting used for electrical safety is supplied in a range of dielectric grades suitable for low- to high-voltage applications. Typical voltage ratings span from around 450 V up to 36,000 V; material composition and thickness are factors that affect dielectric behaviour. Where required, matting meeting IEC 61111:2009 may be specified or provided on request. Consideration of workplace risk, working voltage and applicable standards is relevant when selecting matting for switchrooms, plant rooms, workshops or marine environments.

Product formats, selection and technical advice

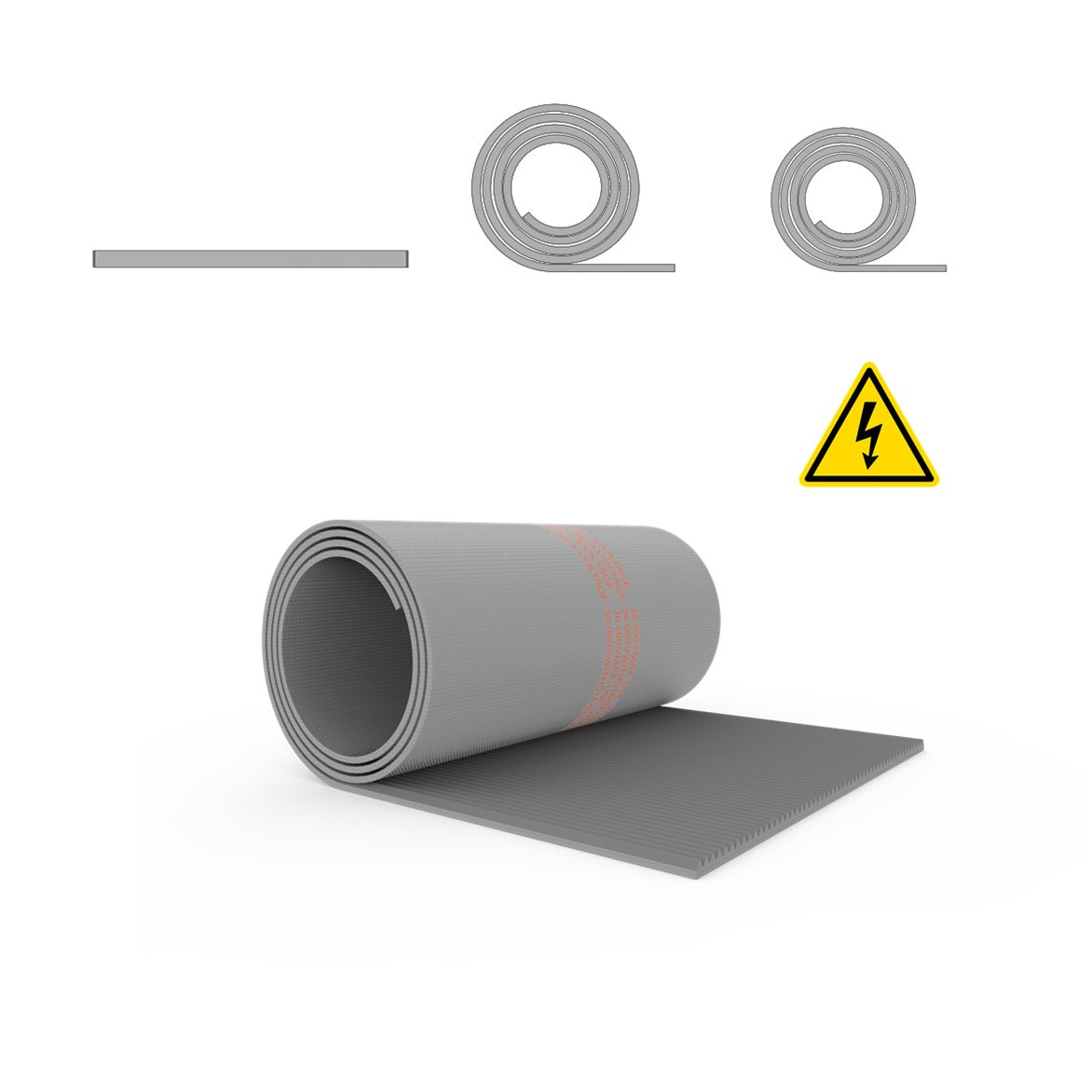

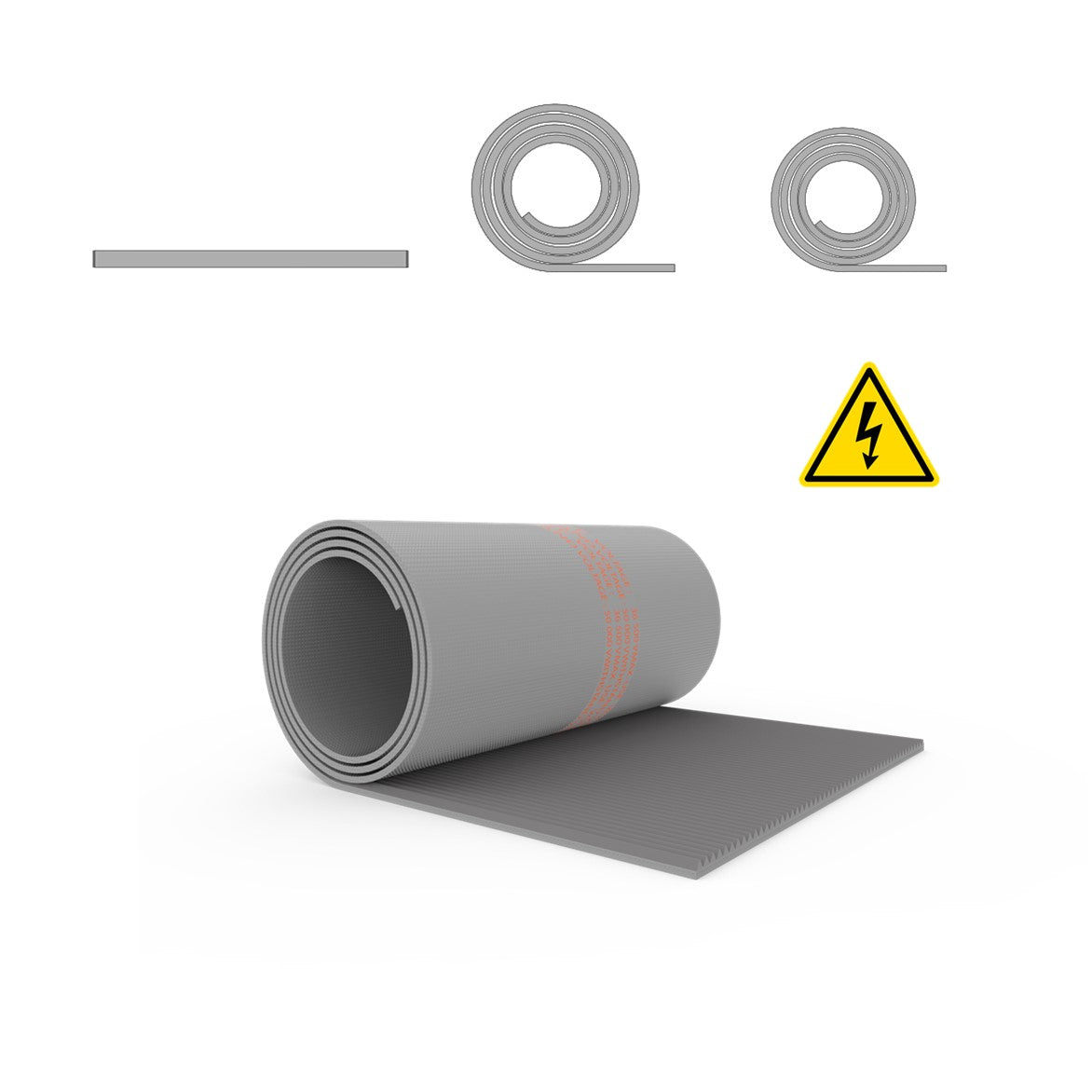

Products are produced in multiple sheet sizes and thicknesses to support different installation layouts, and options for cut-to-size or modular formats can be considered during specification. Laboratory testing data, handling guidance and installation recommendations can be requested to support procurement and compliance checks. For assistance with product selection or to discuss technical requirements, contact the technical team for advice. RuplaTec supplies industrial rubber matting and further information is available in the rubber electrical matting collection.