1

/

of

1

IN STOCK

IN STOCK

QUALITY

QUALITY

FAIR PRICES

FAIR PRICES

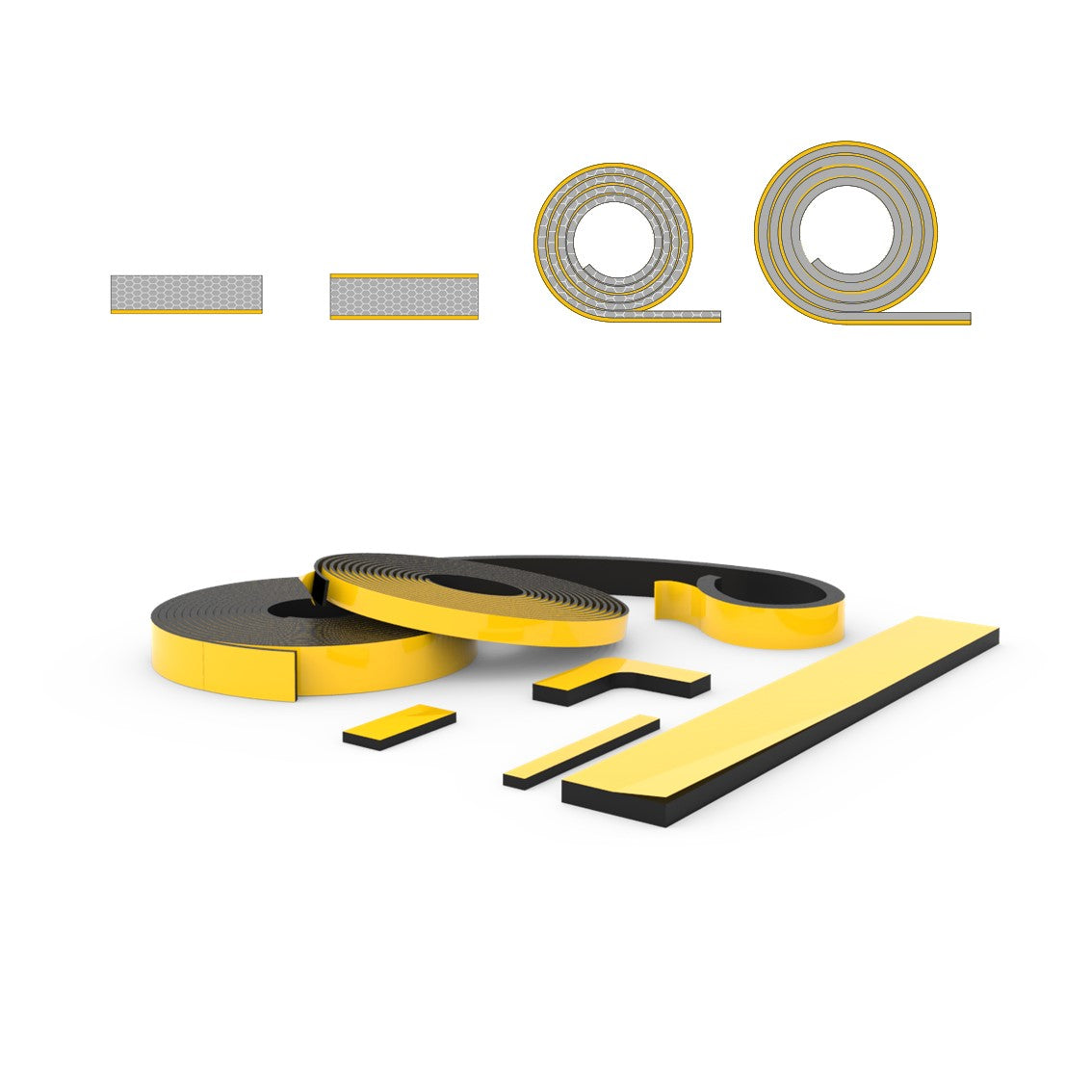

Self adhesive rubber strips

Self adhesive rubber strips

Self adhesive rubber strips in neoprene featuring a pressure-sensitive adhesive backing. This solid rubber sealing strip provides resilient compression sealing, vibration damping and abrasion resistance for gaskets, edge protection and general sealing applications. The neoprene compound offers good weathering and moderate chemical resistance while the adhesive backing ensures secure bonding to metal, plastic and painted substrates.

Available in multiple types and sizes to suit sealing, padding and isolation tasks; strips can be cut to length or supplied as rolls. For material selection or application-specific guidance contact our technical team. See the cellular rubber collection for related products.

Shipping & Returns

Shipping & Returns

Regular price

€0,01 EUR

Regular price

Sale price

€0,01 EUR

Unit price

/

per

Taxes included.

Product specifications

- Width: mm

- Height: mm

- Material: