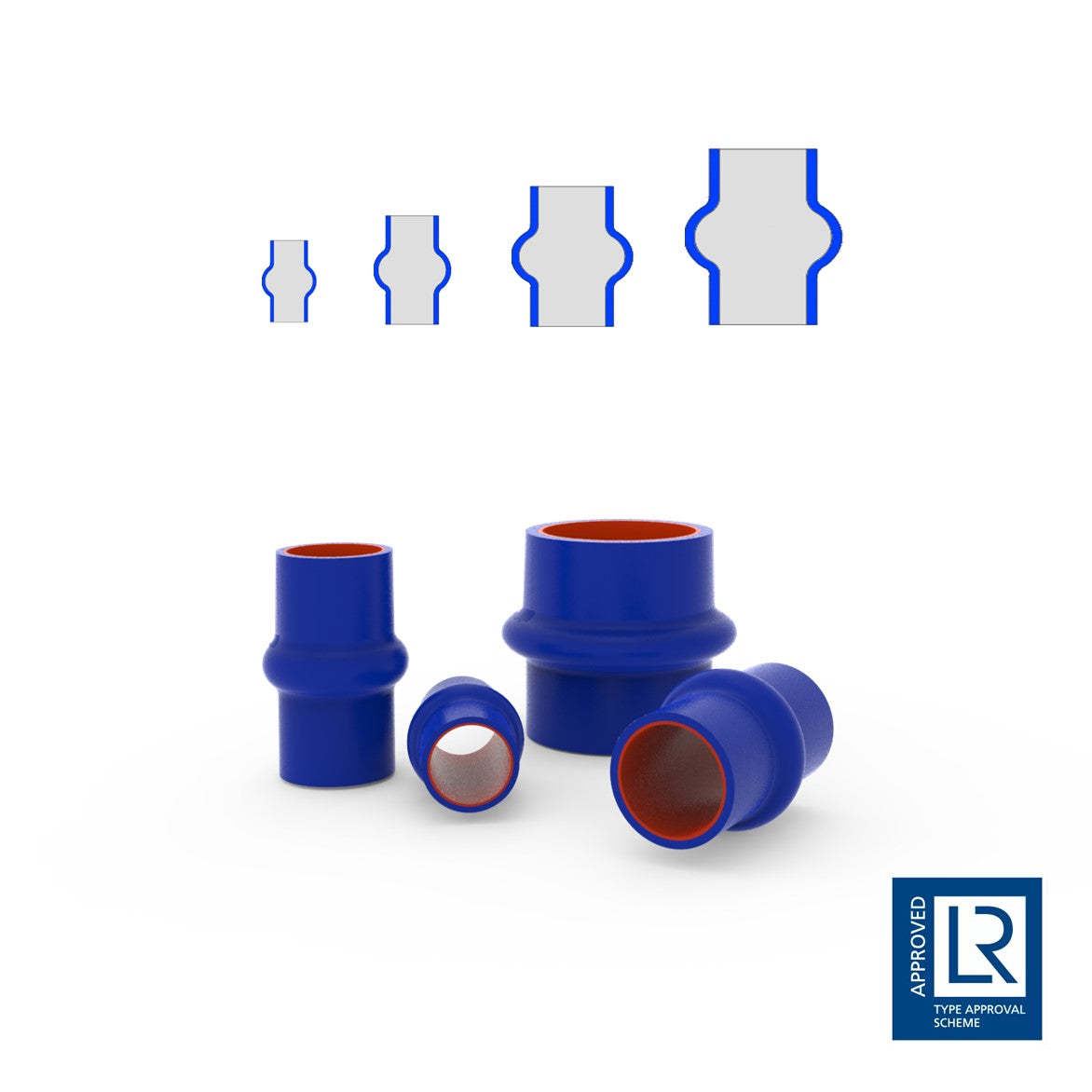

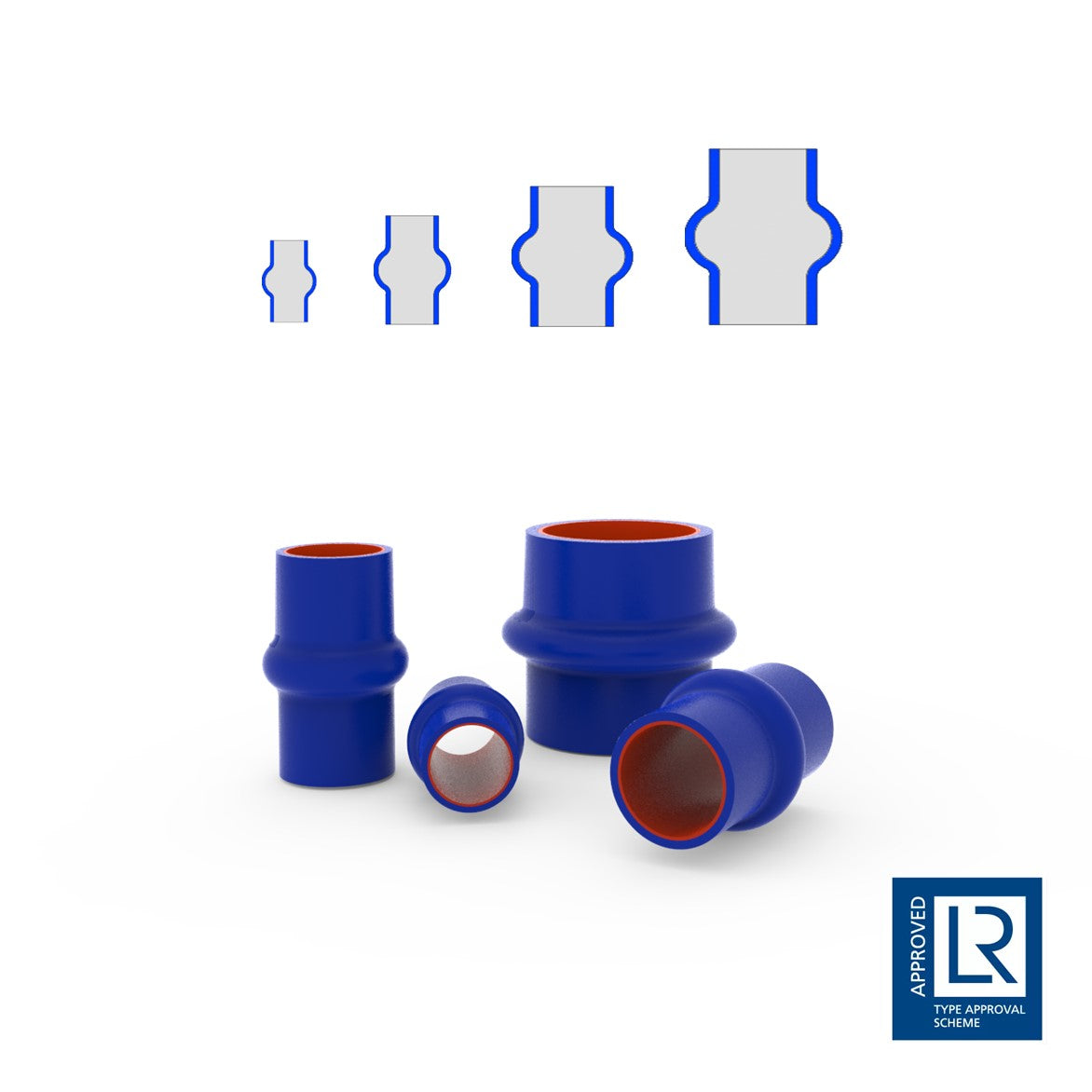

Silicone hump hoses and bellows for industrial connections

Silicone hump hoses and bellows provide flexible, high-temperature resistant connections commonly used in engine intake systems, ducting, and vibration-isolating couplings. Available in a broad range of shapes and sizes, these silicone connector hoses are suitable for applications where flexibility, compression recovery and resistance to heat and ozone are relevant design considerations. RuplaTec supplies a range of silicone hoses aimed at industrial and marine customers; material options and construction details can be discussed with our technical team.

Sizing, selection and technical support for silicone hoses

Selection typically considers inner diameter, wall thickness, profile and required axial or lateral movement. For project-specific selection, dimensional drawings, material information or bespoke lengths may be provided on request where available. Typical application notes include pressure range compatibility, temperature limits and reinforcement options, but suitability should be confirmed against the specific operating conditions. For an overview of standard shapes and variants see the silicone hoses range or contact our team for application advice and supply options.