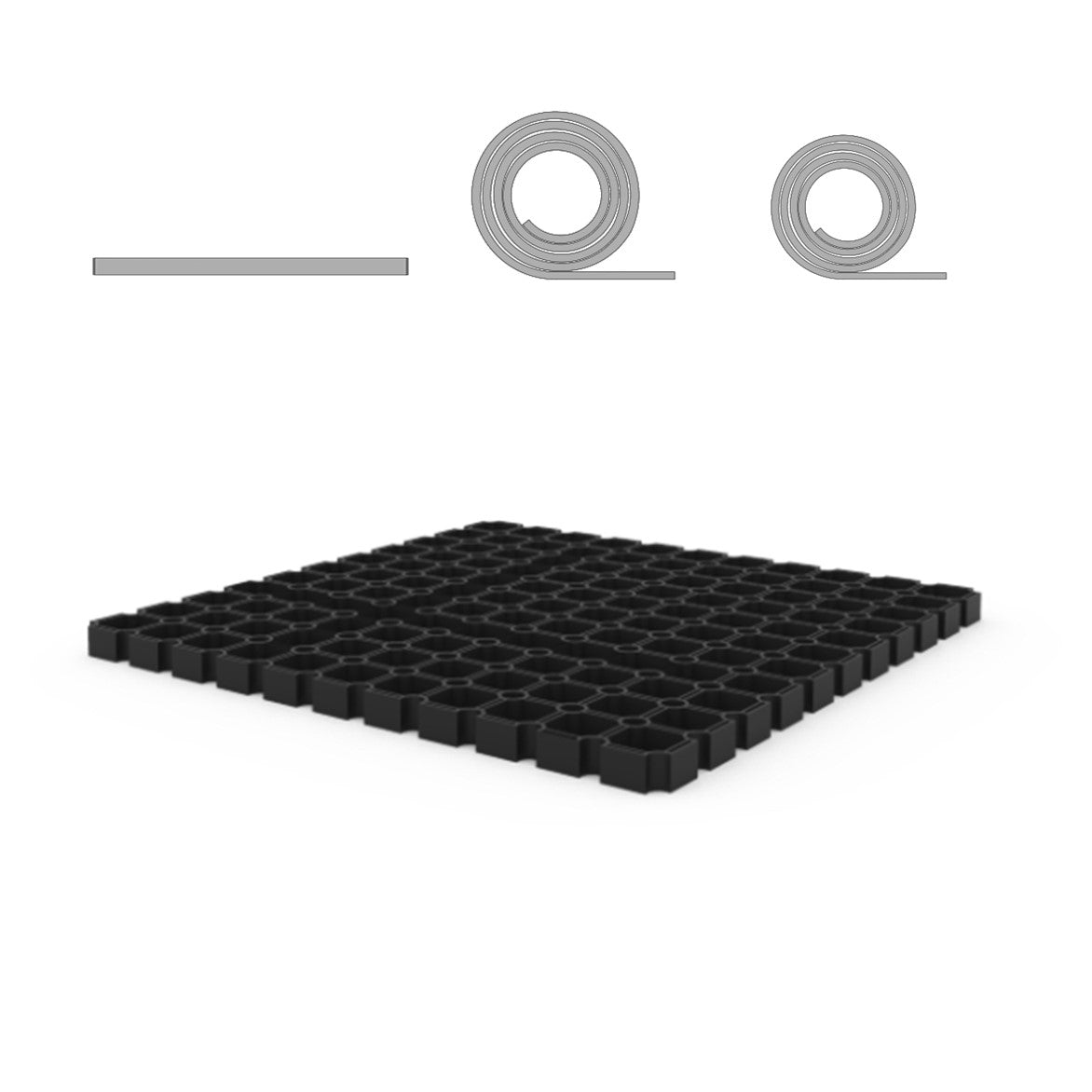

Honeycomb rubber matting — sizes and product overview

Honeycomb rubber matting is supplied in three standard sizes to suit a range of entrance and floor applications. One standard dimension of 91 cm x 152 cm is commonly used for regular doorways and threshold areas, with other sizes available to match different opening widths and layouts. RuplaTec supplies this style of matting as part of its rubber matting assortment; detailed size options can be confirmed on request.

Applications, performance and maintenance guidance

This honeycomb design is used where surface traction, debris retention and drainage are considerations, for example in commercial entrances, workshop thresholds and light industrial walkways. Depending on site requirements, the matting can be placed on level, clean surfaces and may be trimmed to fit around fixtures. Routine maintenance typically involves removal of loose debris and periodic washing; specific cleaning methods will depend on the installation environment and material composition. For advice on suitability for particular environments, contact our technical team.

Specification options and ordering

Standard size options are offered alongside possible cut-to-size supply or bulk quantities where required. Technical data, dimensional tolerances and material options can be discussed with procurement or engineering contacts. For related products and alternative matting formats, see the rubber matting collection or contact our team for application-specific advice.