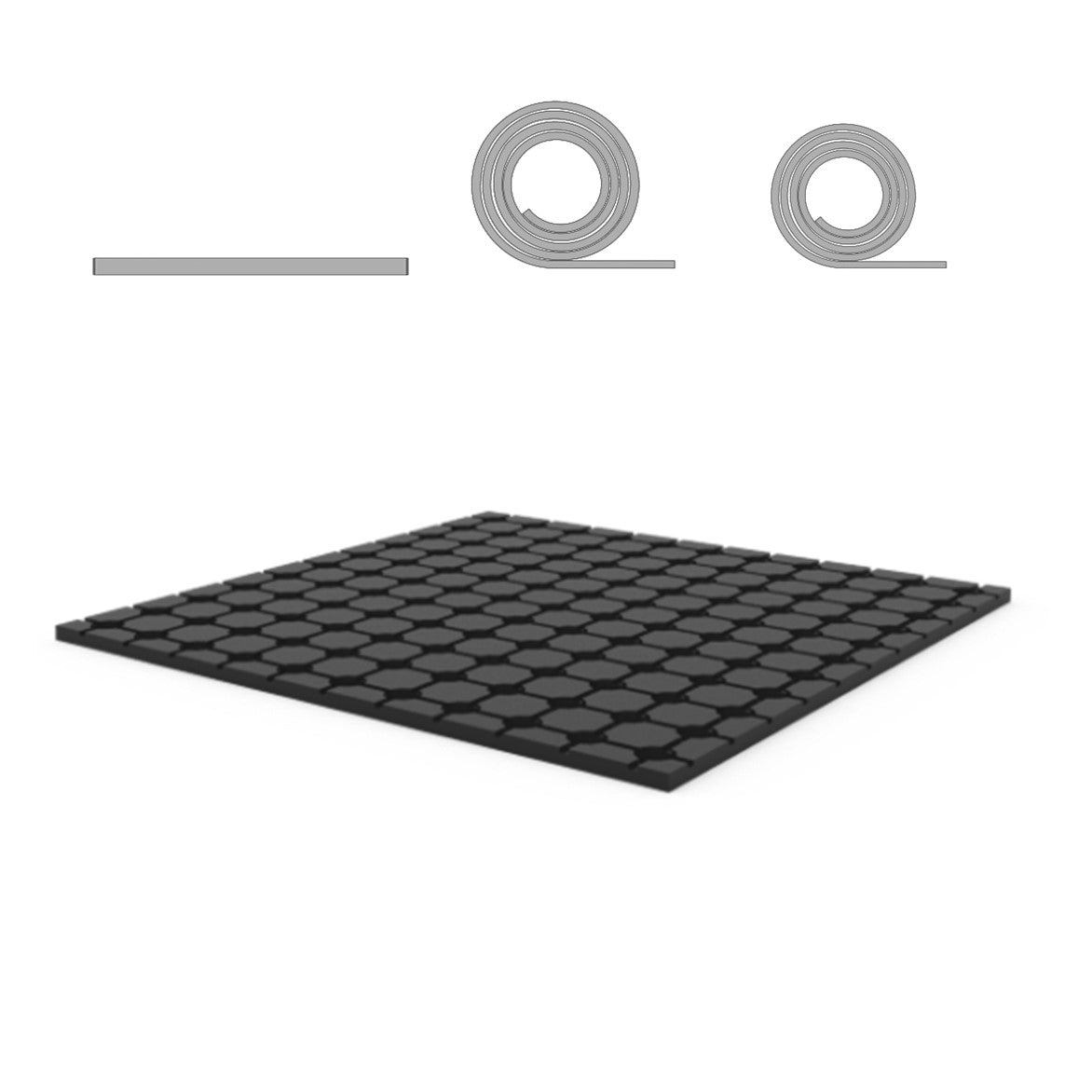

Open ring rubber mat — design and industrial applications

Open ring rubber matting comprises a grid-like structure of resilient rubber formed to allow liquid to pass through while maintaining a stable walking surface. The open-ring profile is commonly specified for wet-area environments where drainage and reduced pooling are considerations. Typical sectors that specify this type of rubber mat include shipyards, marine installations, construction sites, transport hubs and general industrial manufacturing.

Products are offered in a range of sizes and formats to suit different walkways, platforms and workstations. Technical buyers can assess surface profile, thickness and shore hardness relative to expected foot traffic, chemical exposure and load conditions; corresponding dimensional information or material options can be provided on request. For a full overview of size options and related matting products, see the rubber matting collection.

Installation, maintenance and procurement advice for open ring rubber matting

Installation methods for open ring rubber mat vary by application and may include loose-lay placement, mechanical fixing or edge‑trimming to fit bespoke layouts. Surface preparation, drainage gradients and edge retention should be considered during specification to ensure a secure and serviceable installation. Routine maintenance typically involves debris removal and periodic cleaning to preserve drainage capacity and slip performance.

When specifying an open ring rubber mat, review material compatibility with chemicals, oil and sunlight for the specific operating environment. RuplaTec supplies technical rubber and plastic products and can be contacted for advice on selecting sizes, material grades or installation options appropriate to an application.